-

Products

-

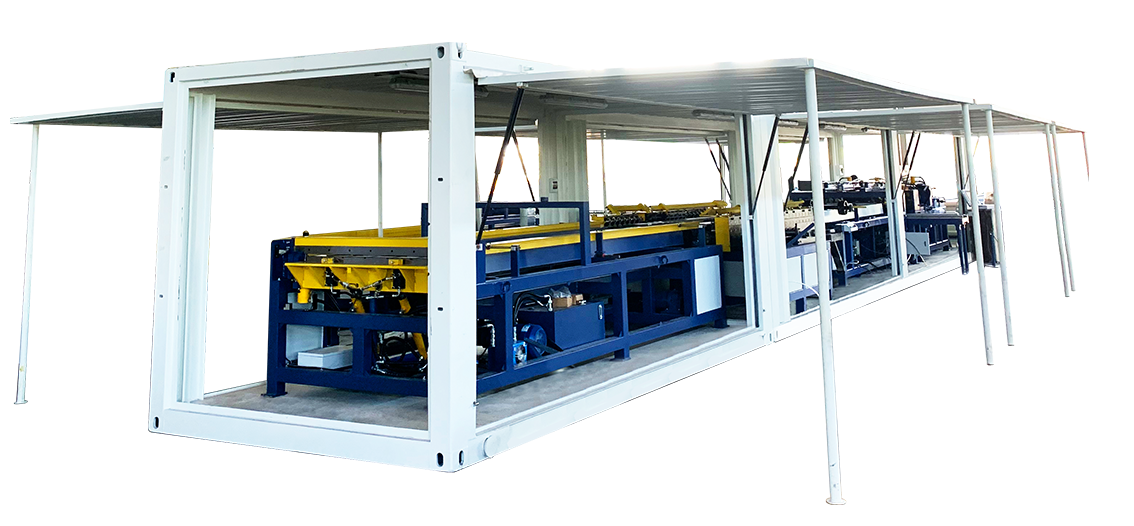

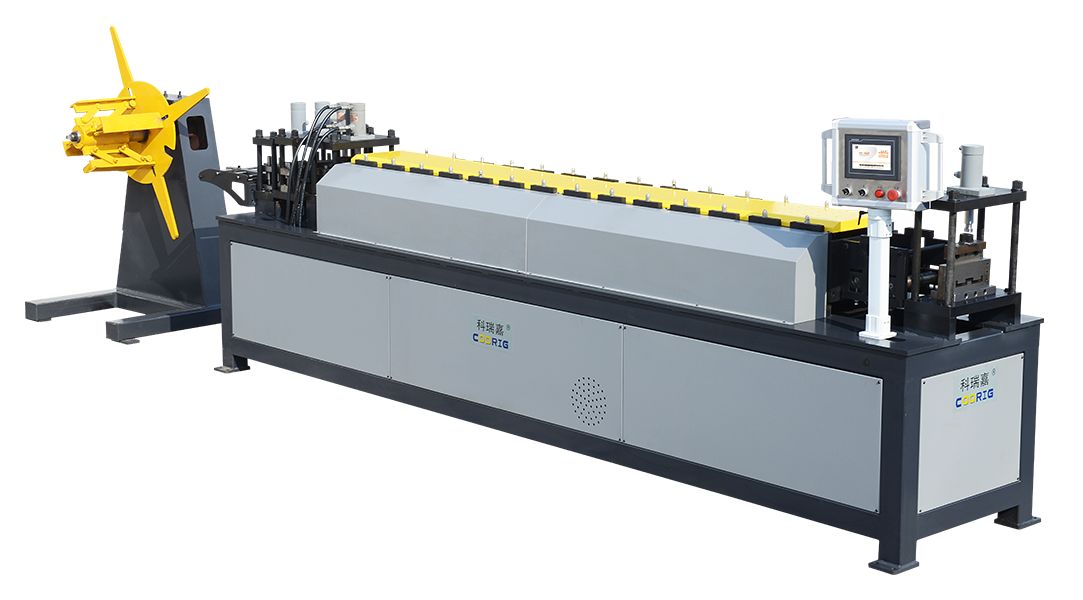

Duct Forming Production Line

-

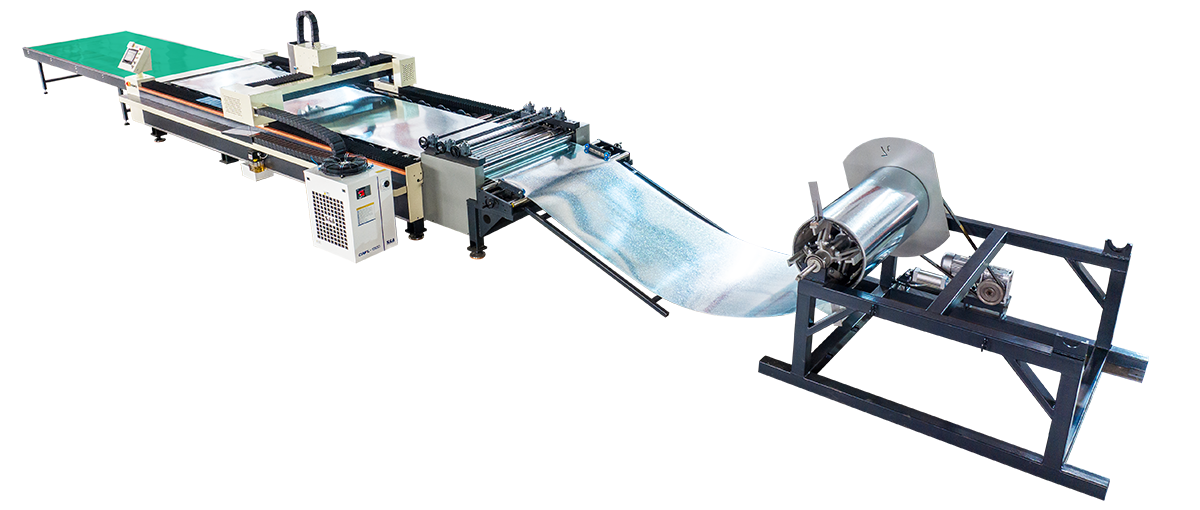

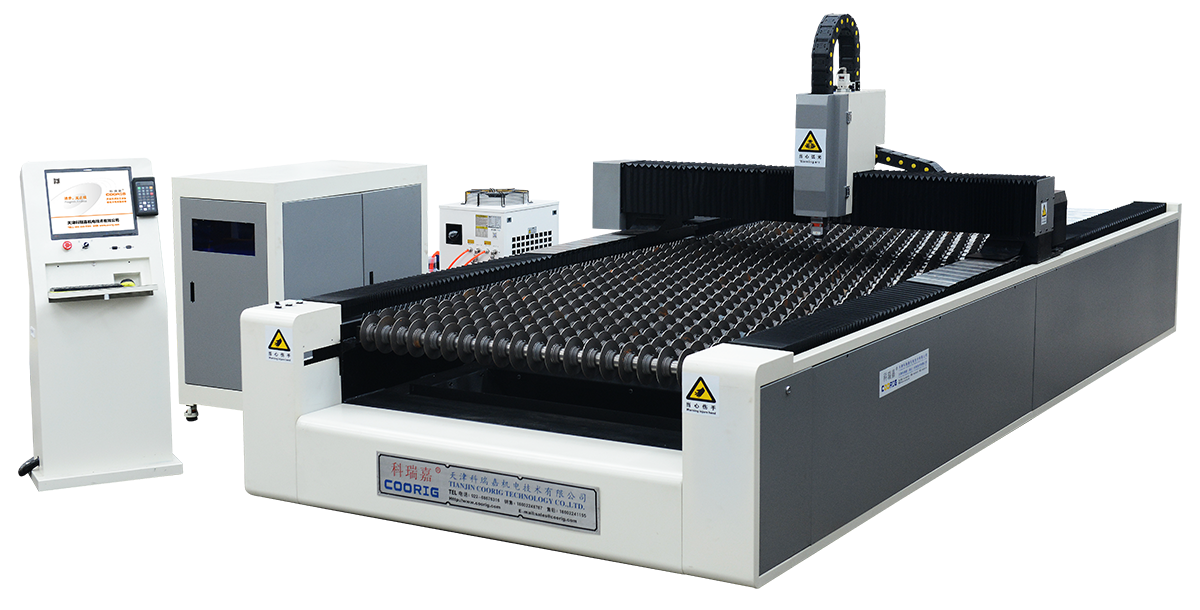

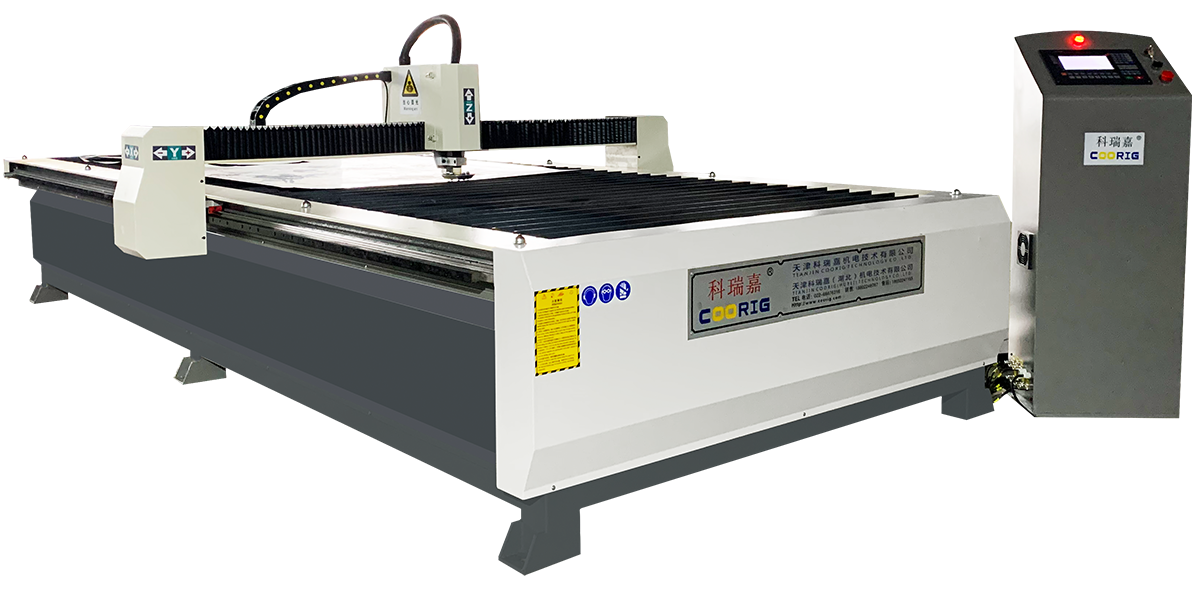

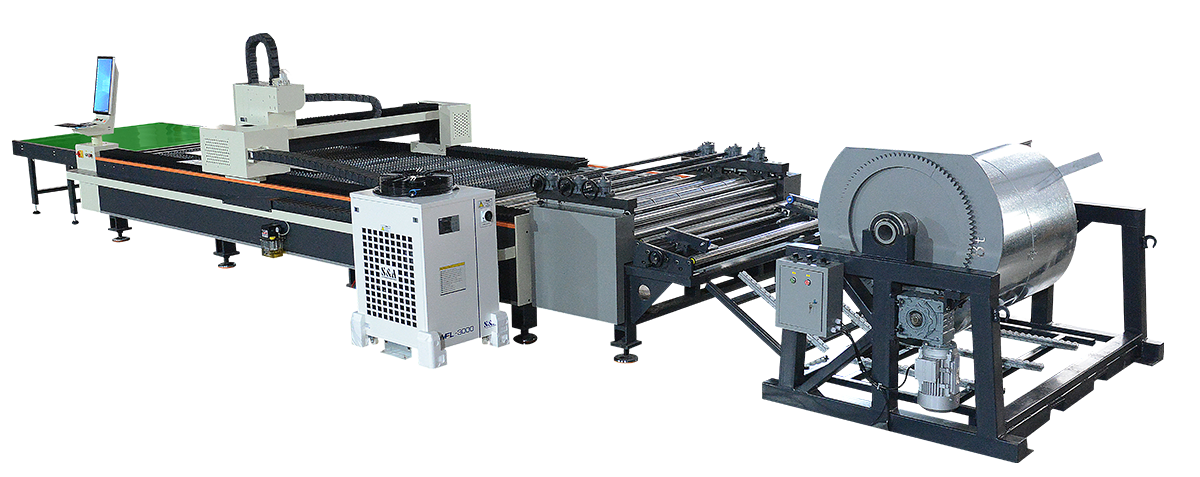

Laser Cutting Machine Series

-

Metal Insulation Pipe Production Line

-

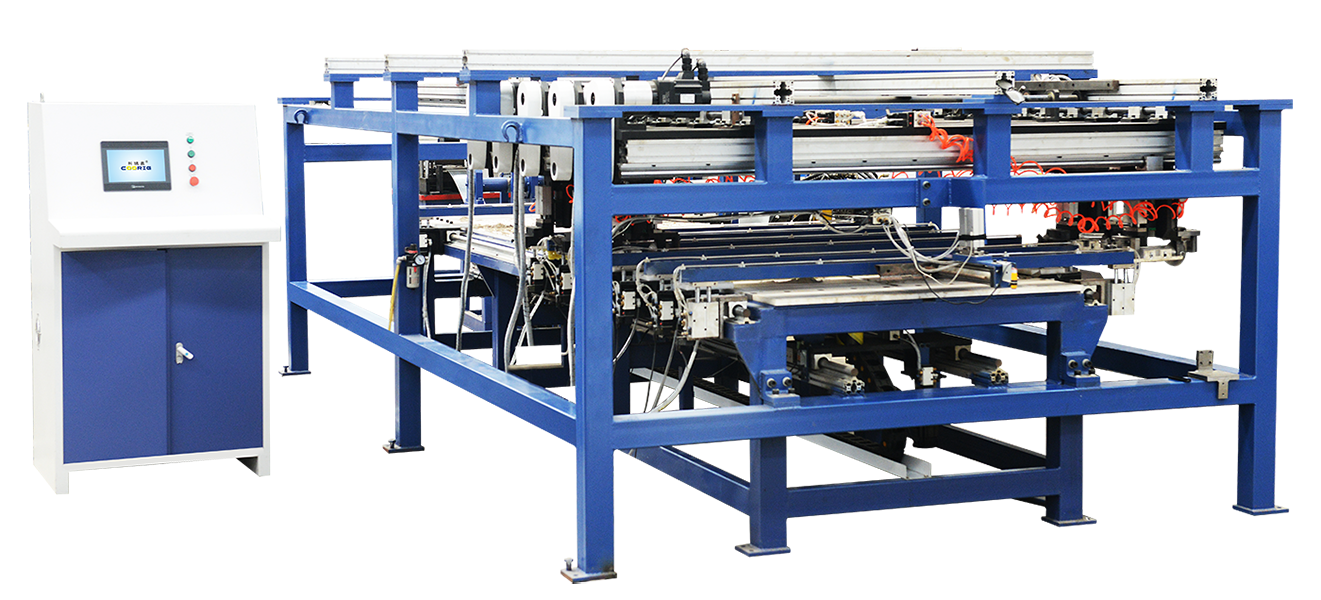

Composite Plate Duct Processing Equipment

-

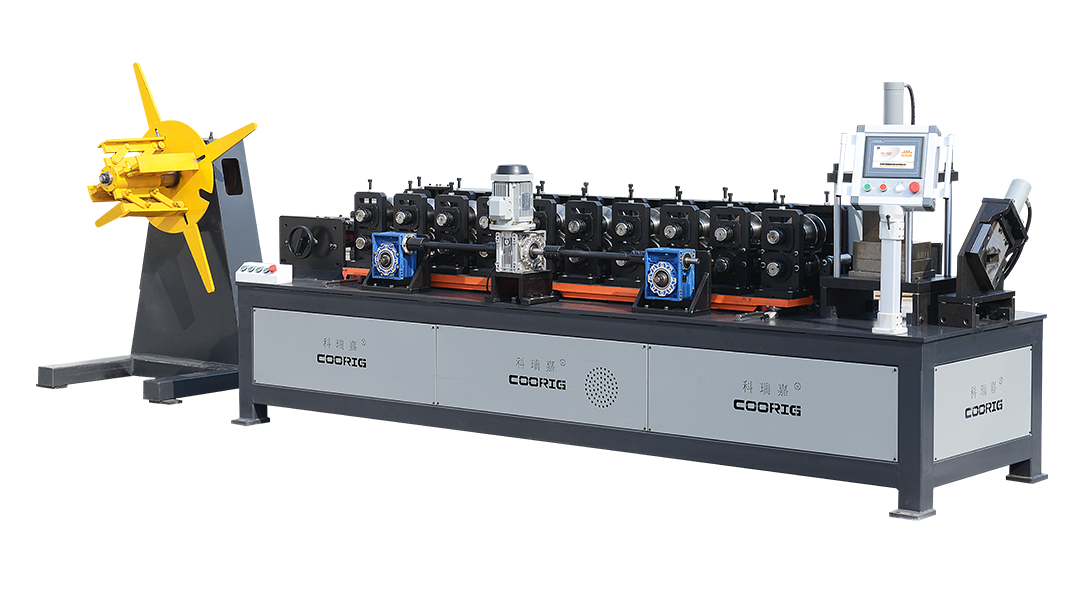

Flange Machines Series

-

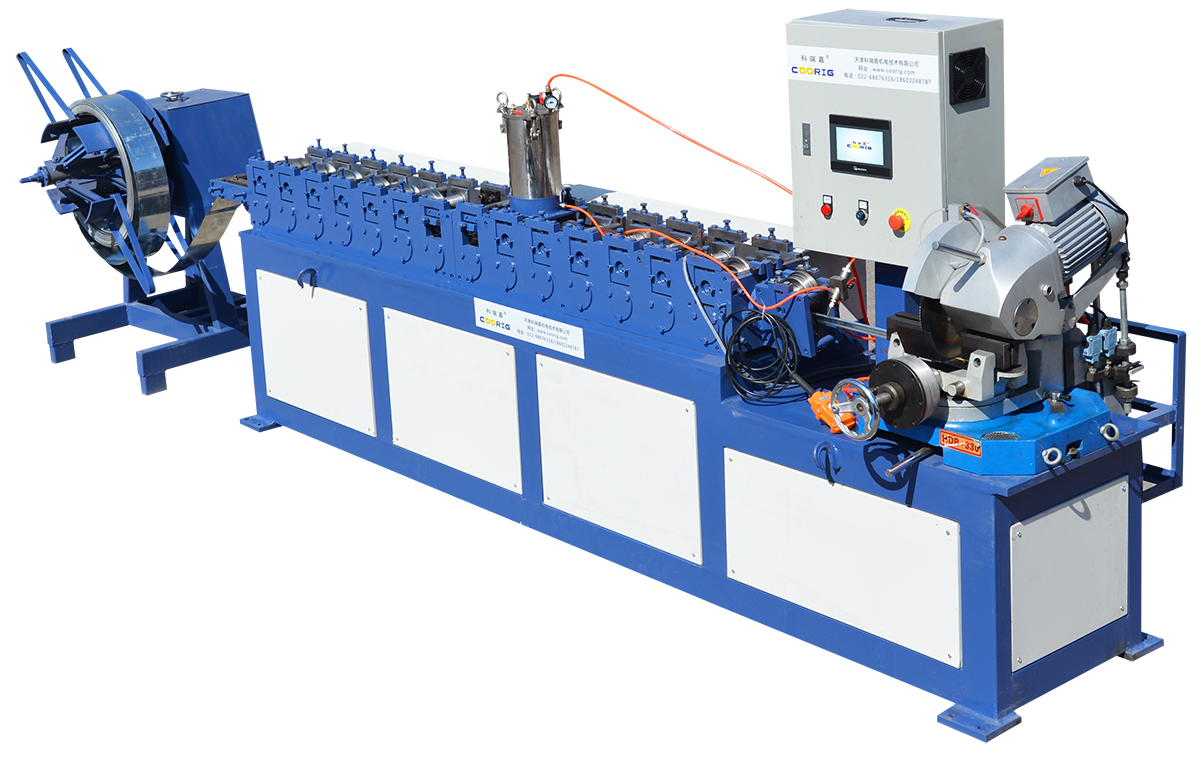

Pittsburgh Lock Forming Machine Series

-

Angle Iron Flange Processing Equipment

-

Square Duct Forming Auxiliary Equipment

-

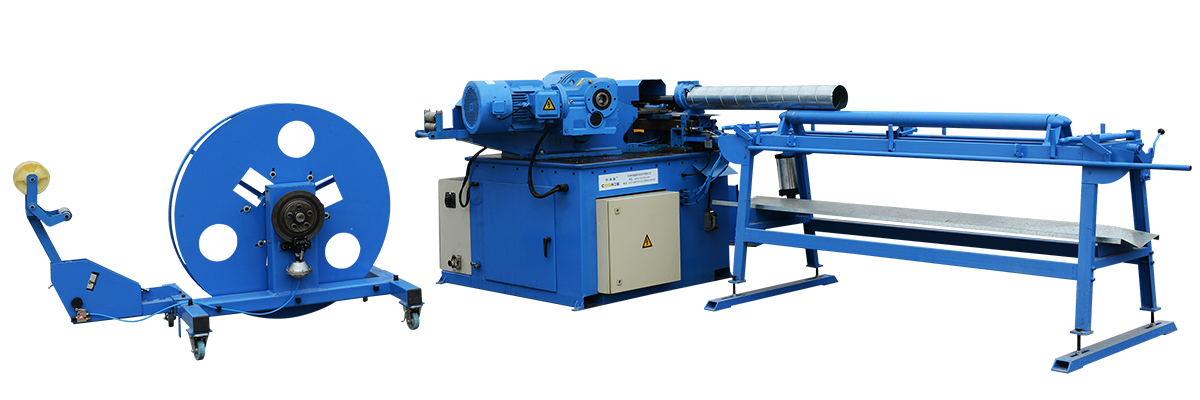

Round Duct Processing Equipment

-

Damper Processing Equipment

-

Fan Coil Equipment

-

Cable Tray Production Line

-

Fire Hose Production Line

-

Comprehensive Support and Hanger Processing Equipment

-

-

Products

Duct Forming Production Line

Laser Cutting Machine Series

Metal Insulation Pipe Production Line

Composite Plate Duct Processing Equipment

Flange Machines Series

Pittsburgh Lock Forming Machine Series

Angle Iron Flange Processing Equipment

Square Duct Forming Auxiliary Equipment

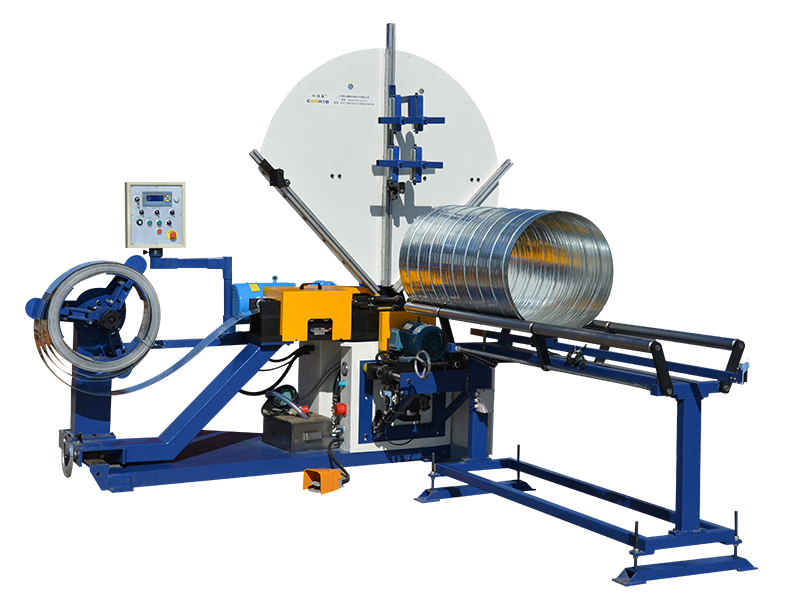

Round Duct Processing Equipment

Damper Processing Equipment

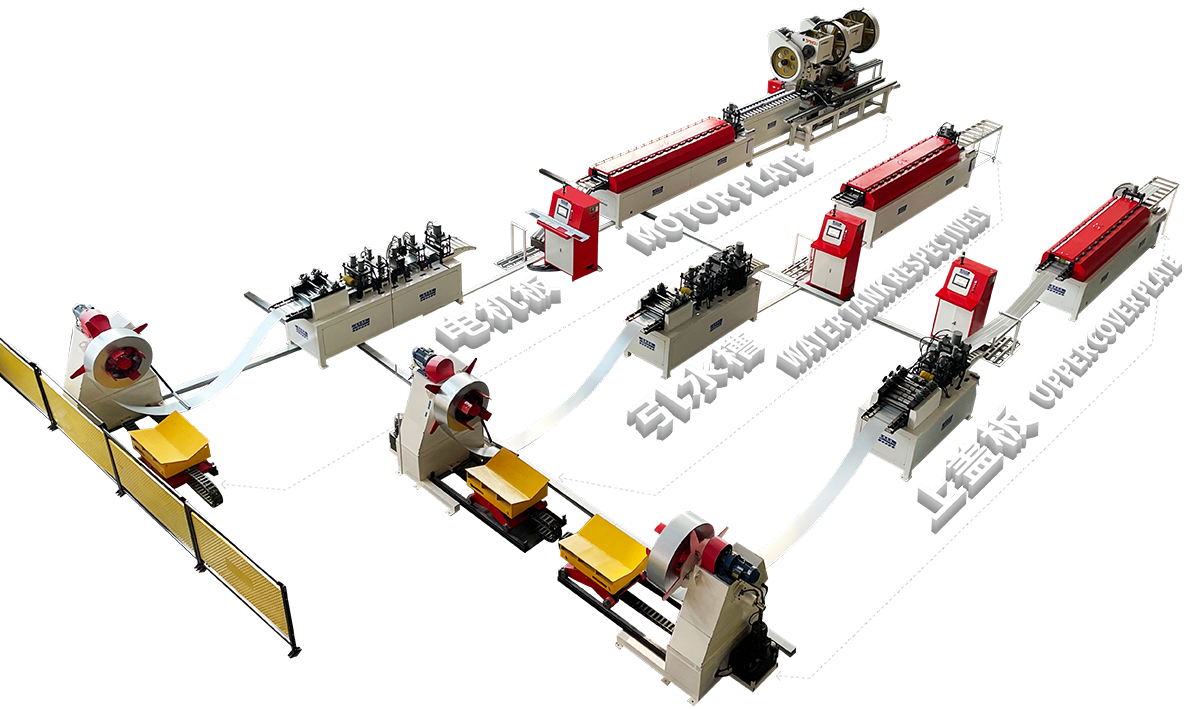

Fan Coil Equipment

Cable Tray Production Line

Fire Hose Production Line

Comprehensive Support and Hanger Processing Equipment

-

Application

-

Services

-

News

-

COORIG

-

Contact

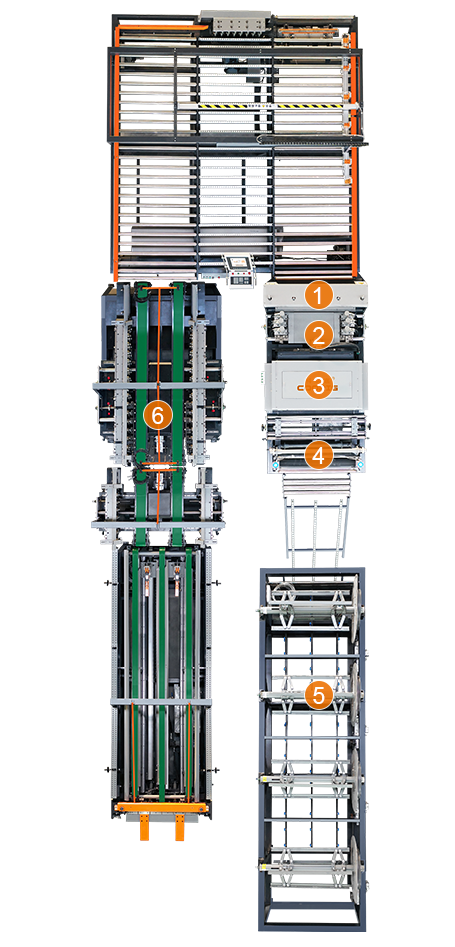

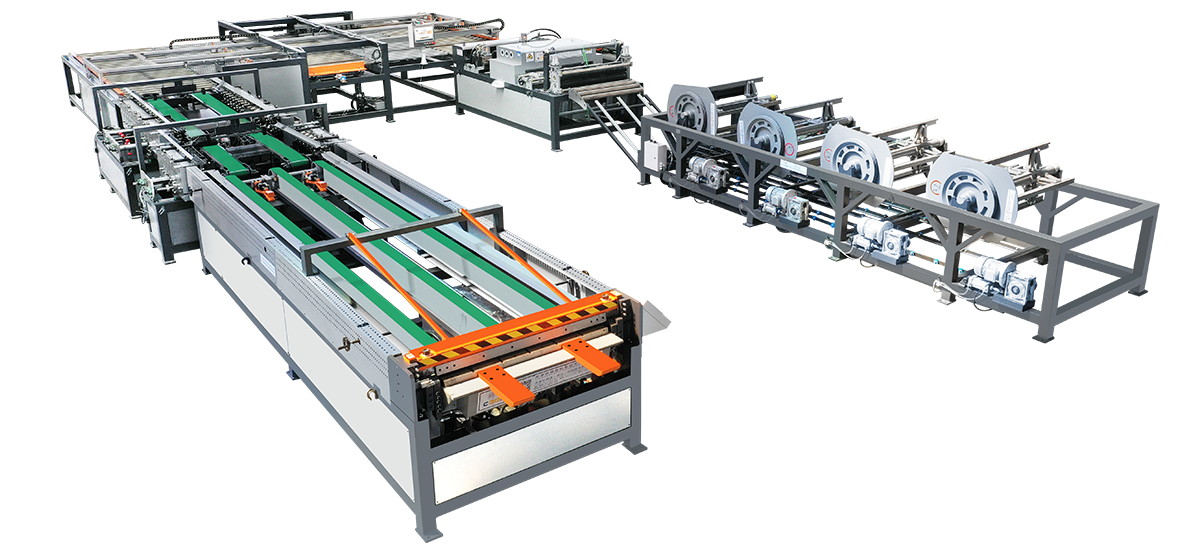

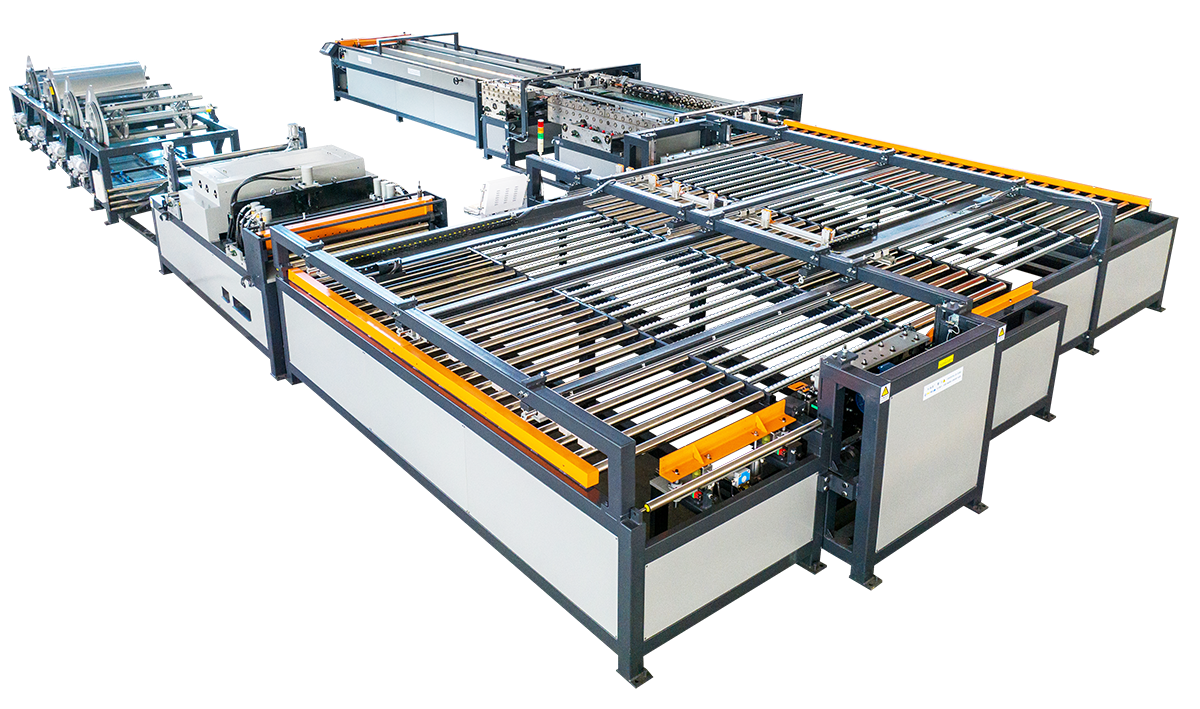

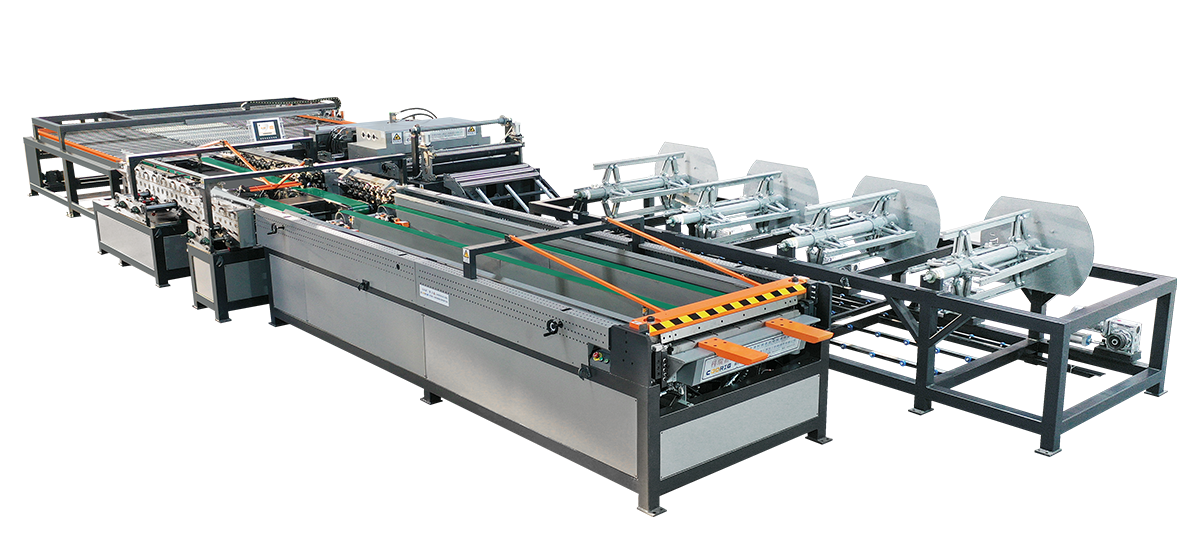

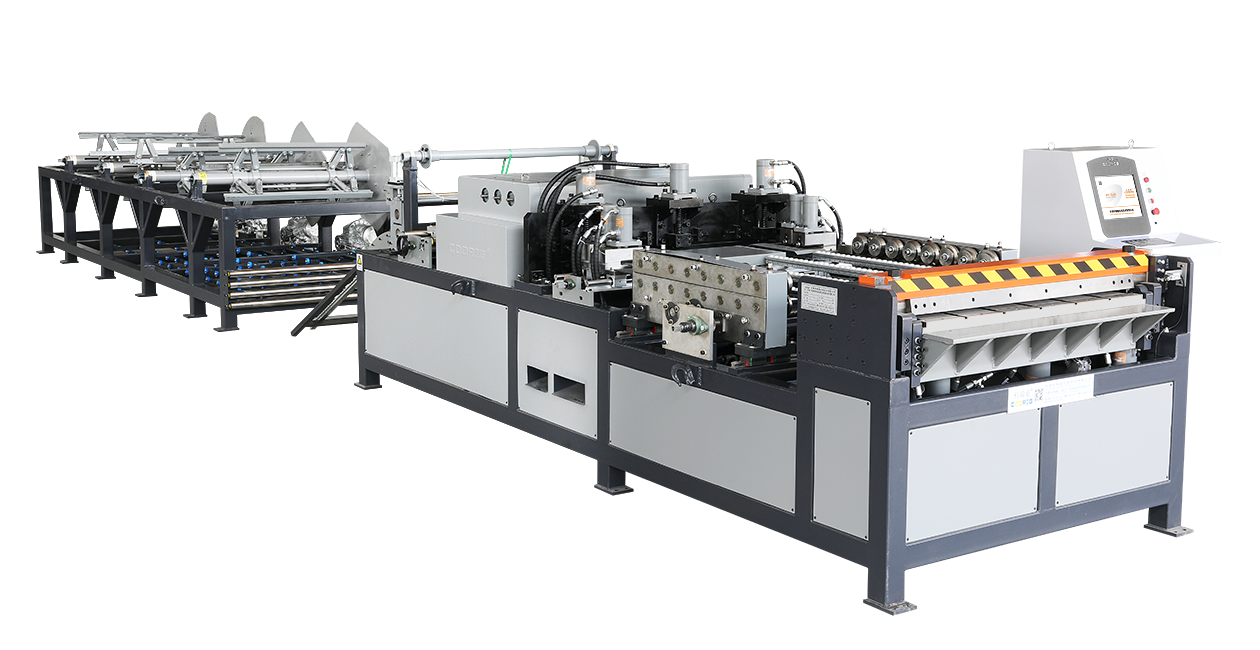

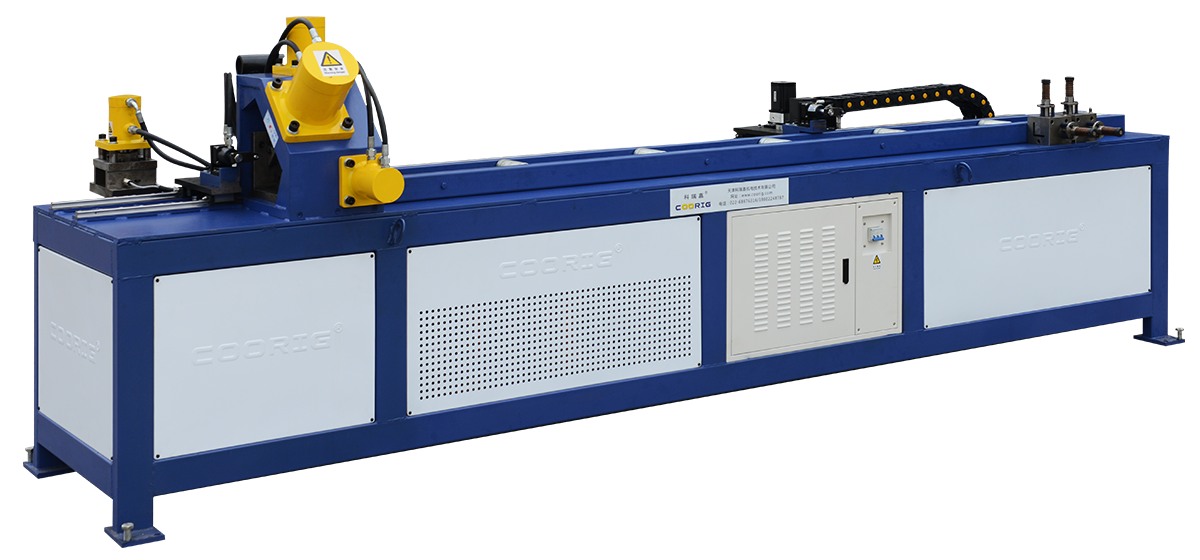

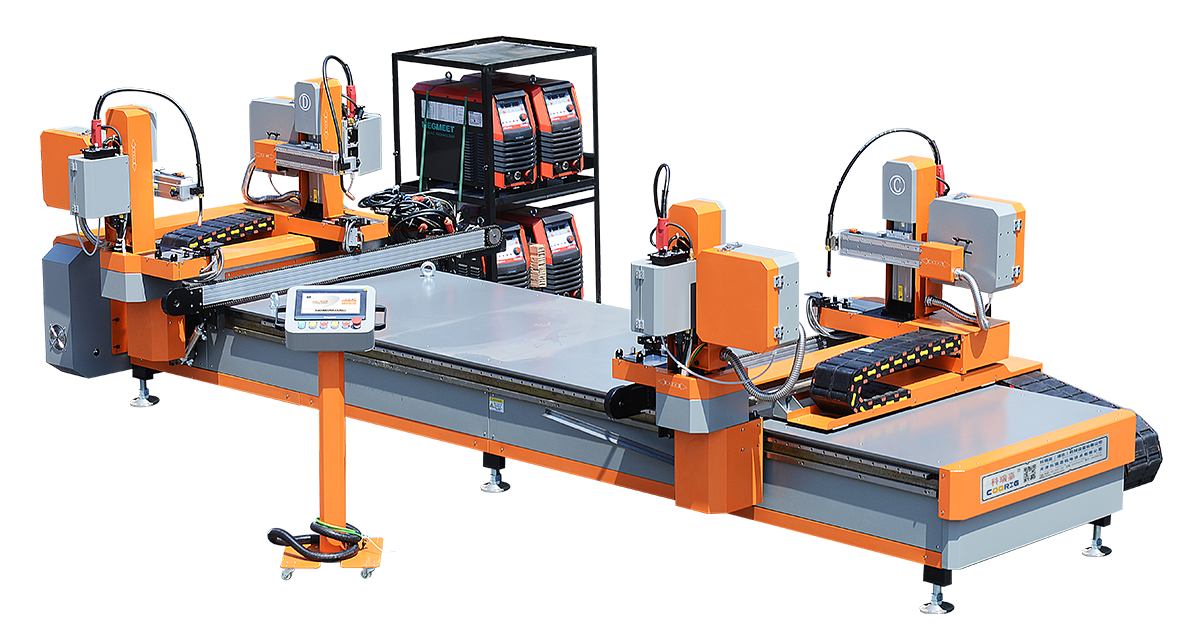

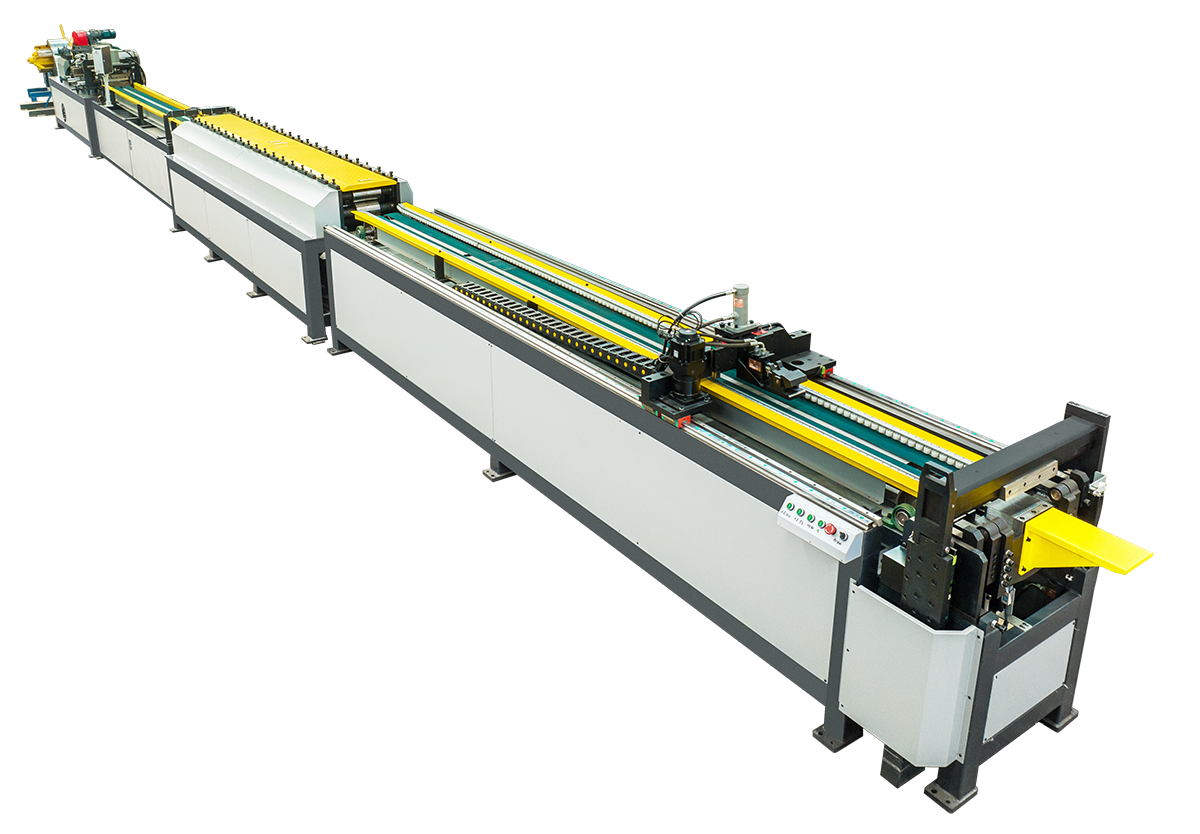

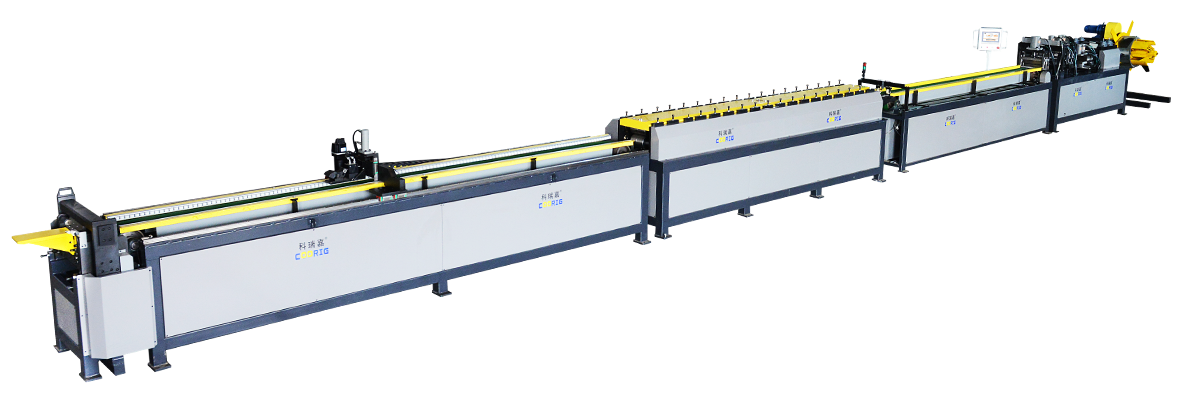

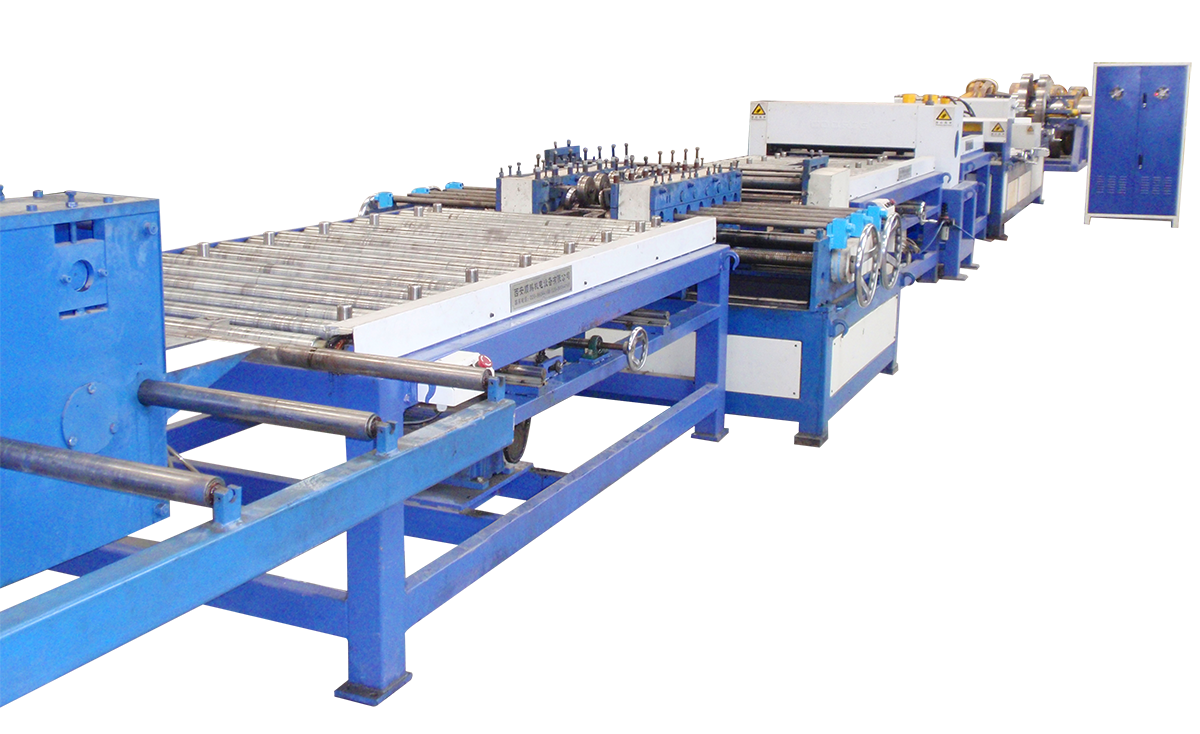

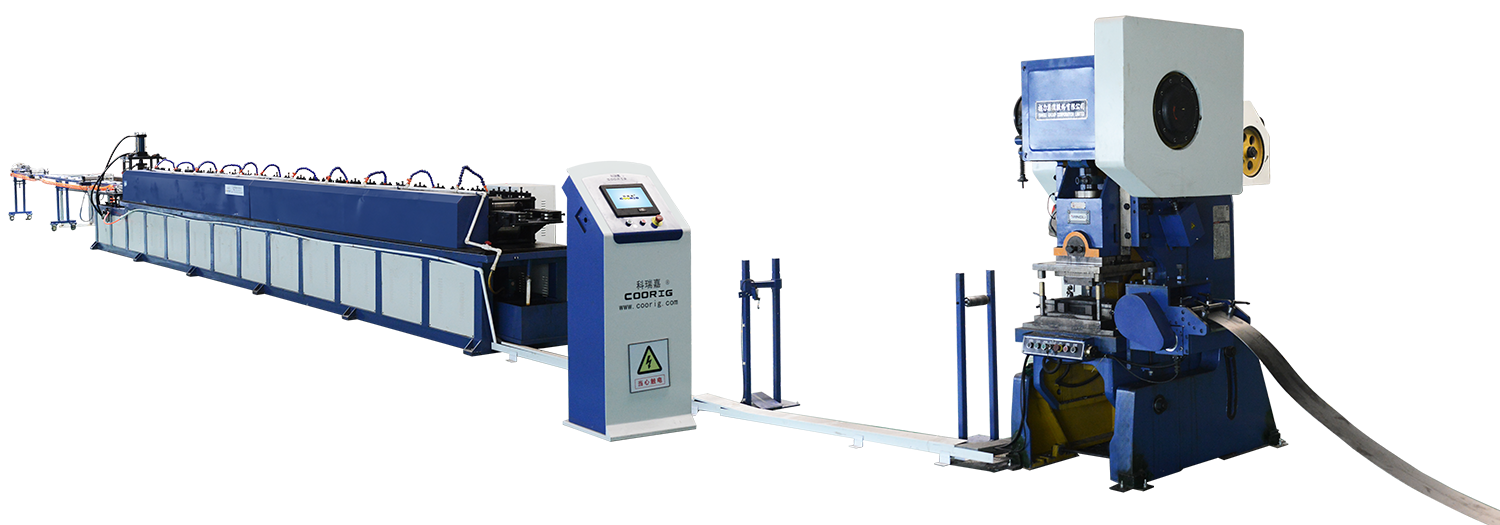

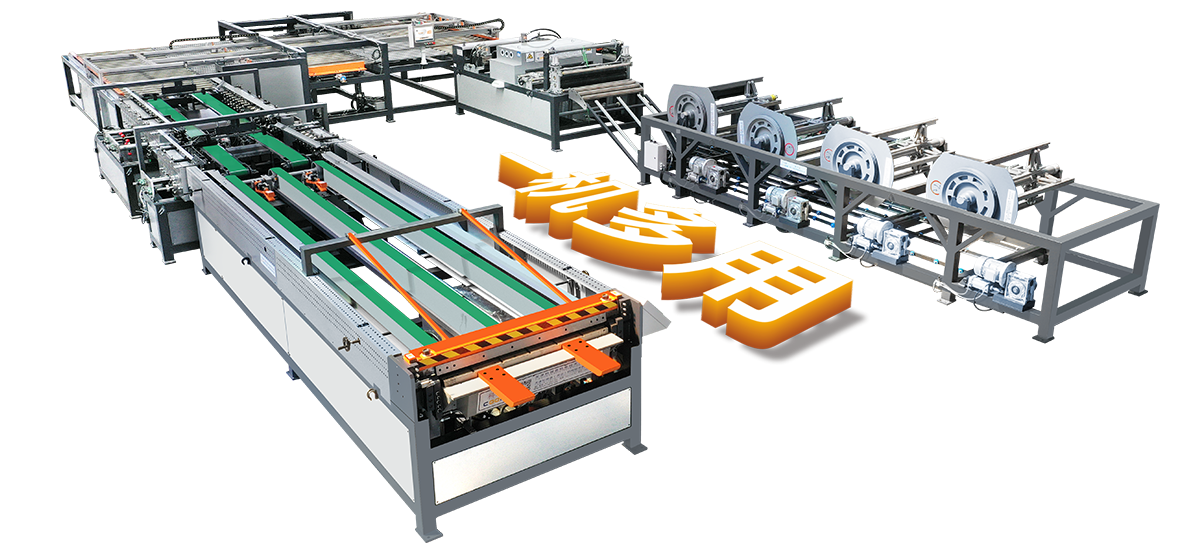

Fully Automatic Double Head Threading Machine

EQUIPMENT DESCRIPTION

-

1. TSAD-DN20-65 fully automatic double head threading machine is mainly used for prefabricated processing of prefabricated fire water pipes in factories. It consists of an automatic feeding system and a double head automatic threading system.

2. The PLC system is used for intelligent control. The feed of threading is controlled by servo motors, which can safely and reliably specify the start and end points. High precision and high strength ball screws are used to meet the needs of different threading lengths and ensure processing accuracy.

3. The opening and closing of the machine head is controlled by the cylinder, and the clamping and loosening of the pipe are controlled by the cylinder. The clamp has a self centering function.

4. Can complete steel pipe specifications of 4 points, 6 points, 1 inch, 1 inch, 2 inch, 1 inch, 5 ", 2 inch, 2 inch, 5", caliber, and can be compatible with automatic threading and automatic loading and unloading of steel pipe products of any length between 1.5 meters (including) and 3.6 meters (including).

MAIN CONFIGURATION

1. Threading hosts 2 sets

2. Discharge rack 1 set

3. Transfering mechanism 1 set

4. Material receiving platform 1 set

5. Including 7 calibers and 14 sets of fixtures

MAIN TECHNICAL DATA

|

NO. |

8001

|

Floor space of the machine

|

8000x3000mm |

|---|---|

Machinable base pipe specification

|

2"~4",length 1.5-3.6m |

Power supply

|

380V/50HZ |

| Equipment power |

15KW

|

Spindle rotation speed of threading

|

0-60rpm |

| Production efficiency |

The efficiency of all specifications of products within the scope of the project shall not be less than a production rhythm of 20 seconds per piece (including loading and unloading)

|

The equipment appearance, configuration and technical parameters are for reference only, the actual products shall prevail.

|

|

-

- HEADQUARTERS

- TIANJIN COORIG TECHNOLOGY CO.,LTD

- Add: Jinghai Developing Zone of Tianjin, China

- Tell: +86 022-68676316 / 68676317 / 68676318

- E-mail: forest@coorig.com

- PRODUCTION BASE

- HUBEI COORIG TECHNOLOGY CO., LTD

- Add: Fengridadao,Developing Zone of Chongyang,Hubei, China

- Tell: +86 0715-3300166 / 3300566

- E-mail: forest@coorig.com

-

- Products

- Duct Forming Production Line

- Laser Cutting Machine Series

- Metal Insulation Pipe Production Line

- Composite Plate Duct Processing Equipment

- Flange Machines Series

- Pittsburgh Lock Forming Machine Series

- Angle Iron Flange Processing Equipment

- Square Duct Forming Auxiliary Equipment

- Round Duct Processing Equipment

- Damper Processing Equipment

- Fan Coil Equipment

- Cable Tray Production Line

- Fire Hose Production Line

- Comprehensive Support and Hanger Processing Equipment

- Services

- After-Sale Service

- Service Network

- Application

- Customer Site

- Video Center

-

WeChat Official Account

-

Mobile Browsings