-

Products

-

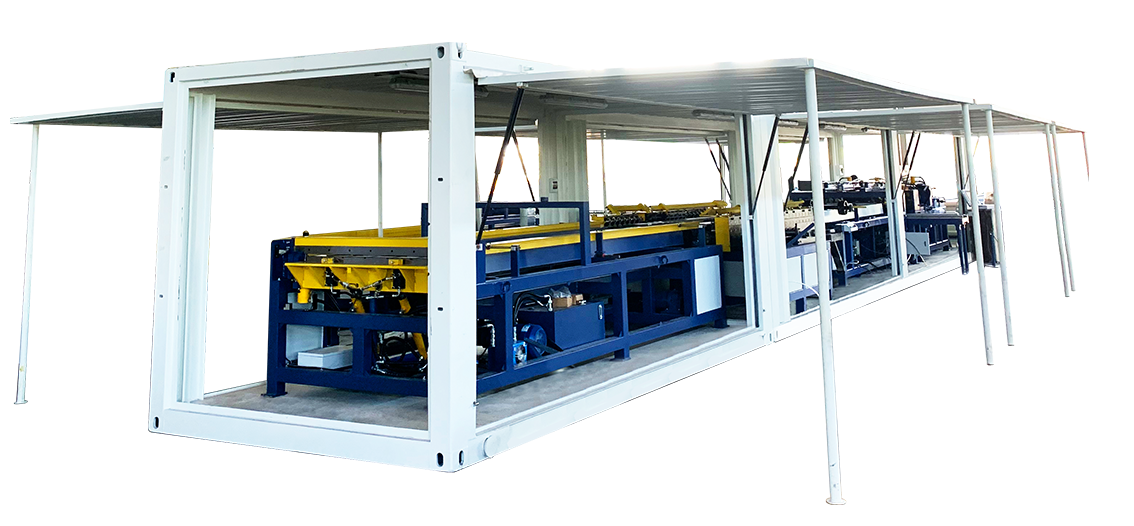

Duct Forming Production Line

-

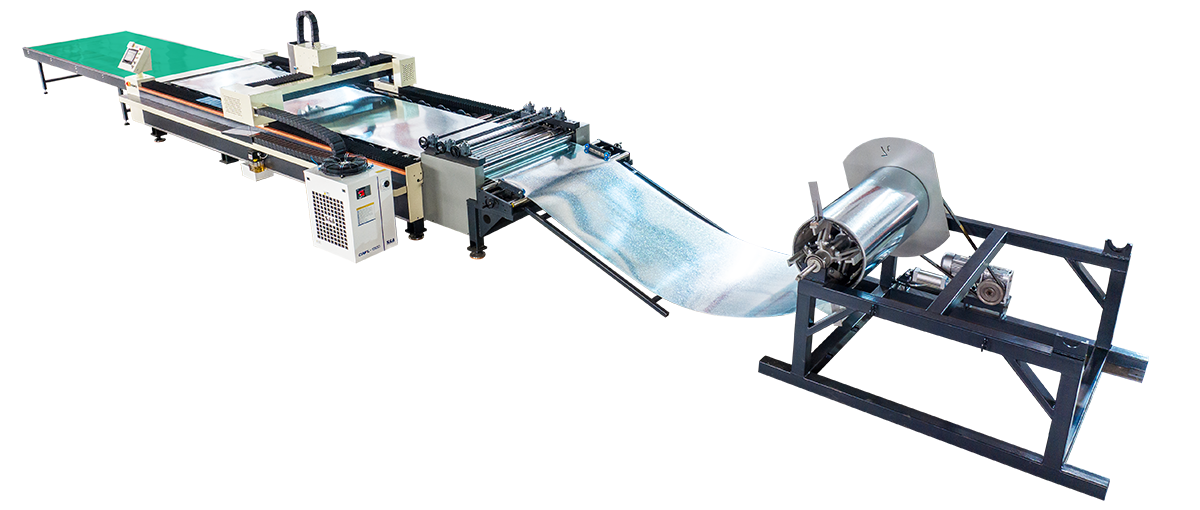

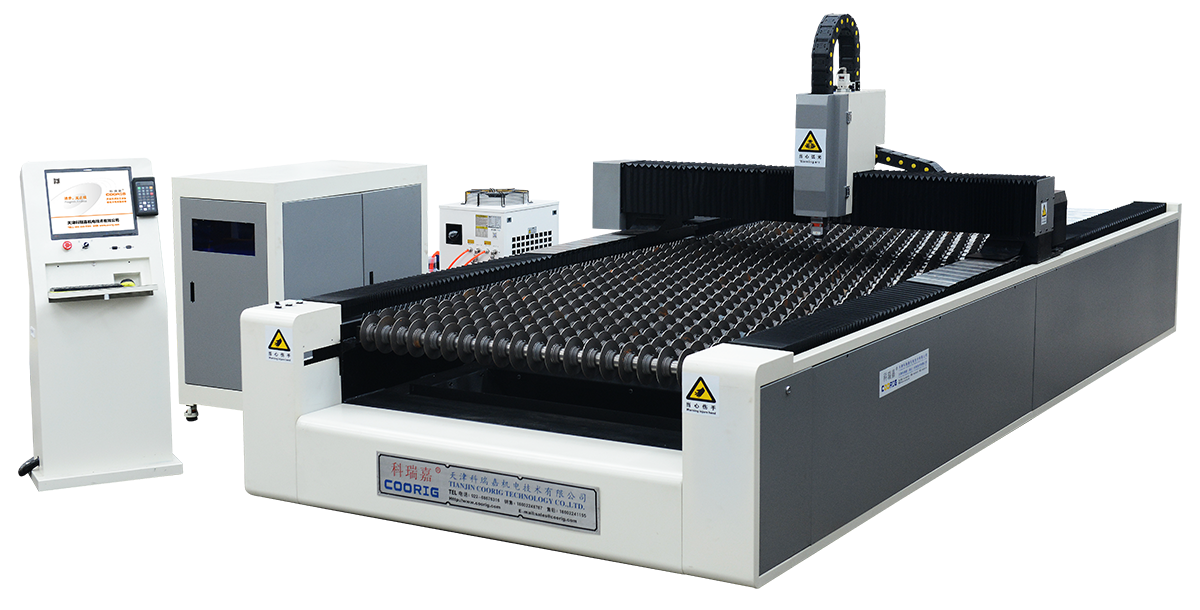

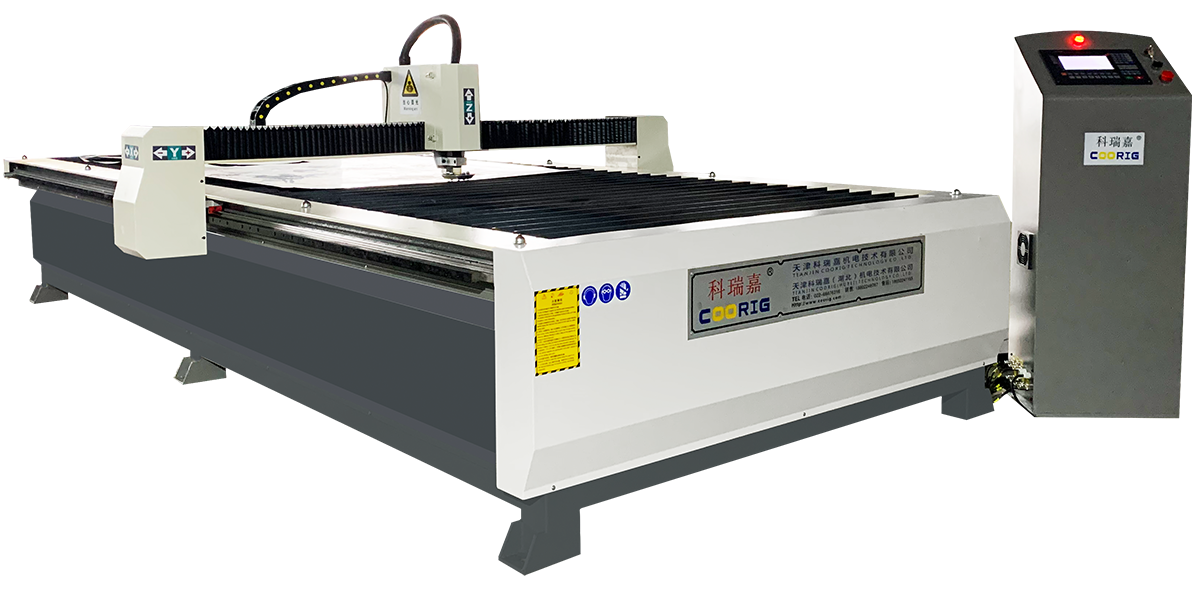

Laser Cutting Machine Series

-

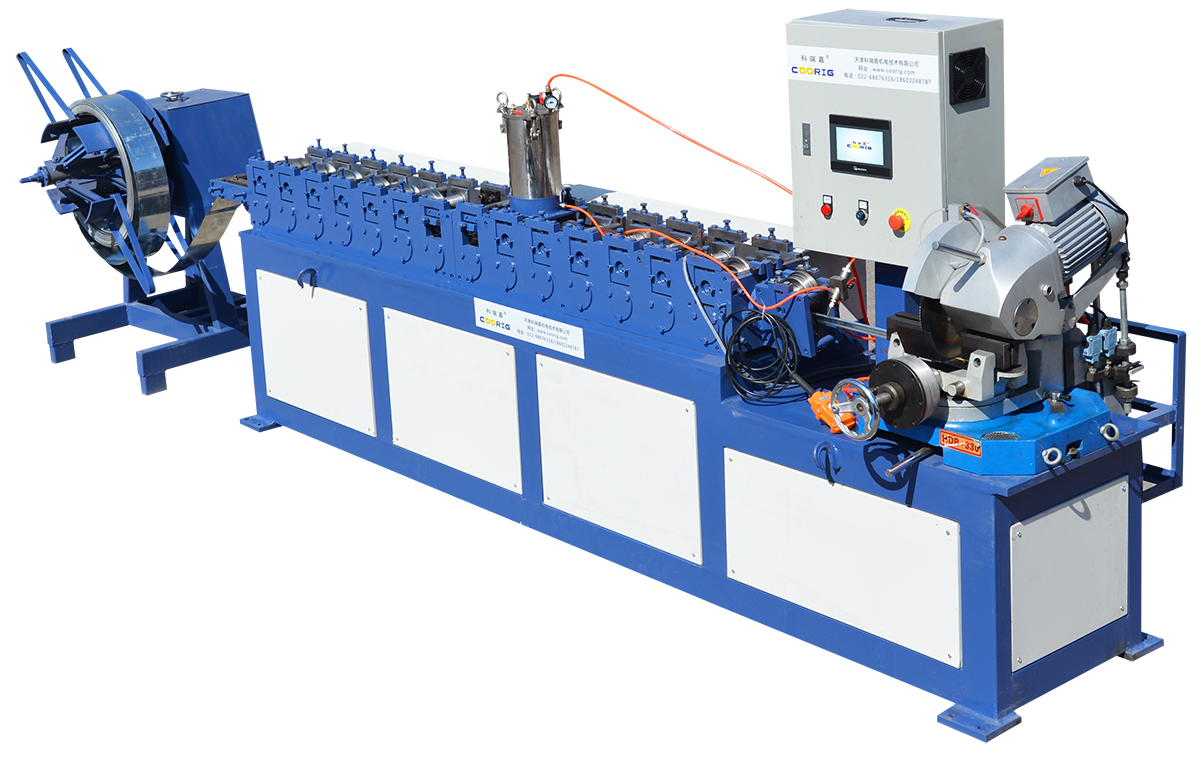

Metal Insulation Pipe Production Line

-

Composite Plate Duct Processing Equipment

-

Flange Machines Series

-

Pittsburgh Lock Forming Machine Series

-

Angle Iron Flange Processing Equipment

-

Square Duct Forming Auxiliary Equipment

-

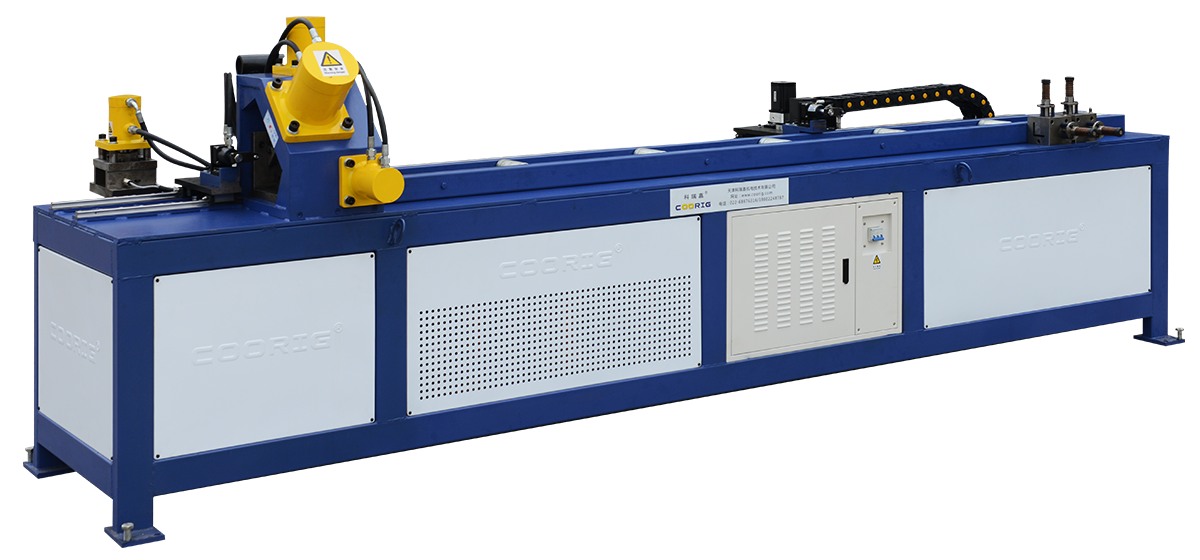

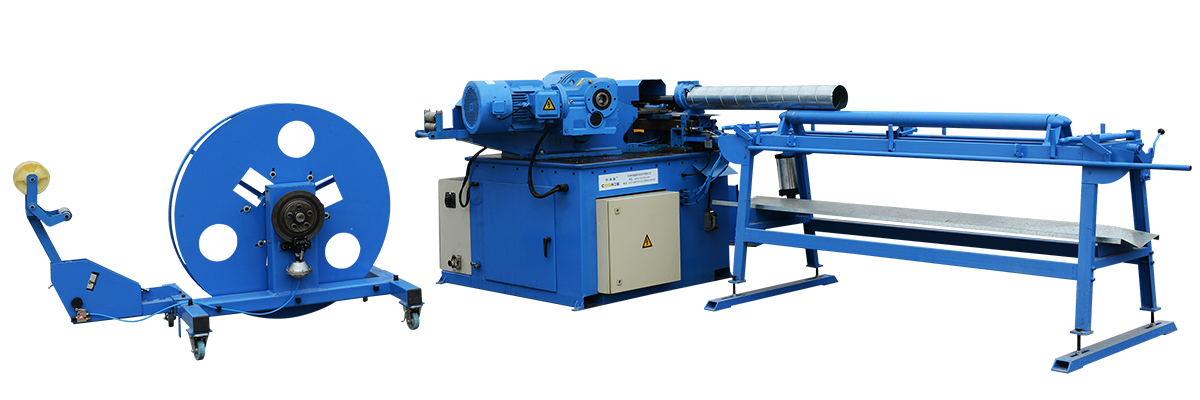

Round Duct Processing Equipment

-

Damper Processing Equipment

-

Fan Coil Equipment

-

Cable Tray Production Line

-

Fire Hose Production Line

-

Comprehensive Support and Hanger Processing Equipment

-

-

Products

Duct Forming Production Line

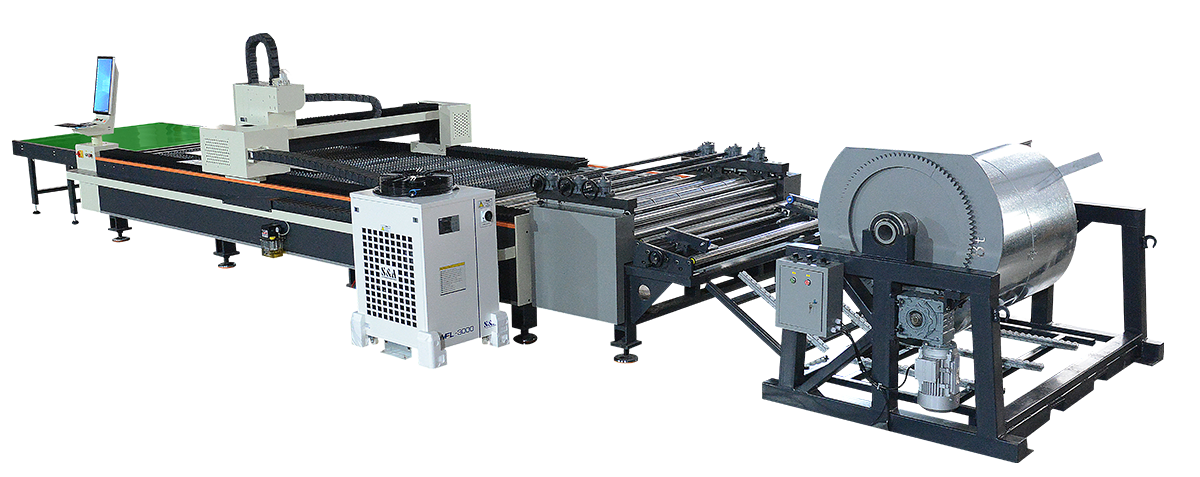

Laser Cutting Machine Series

Metal Insulation Pipe Production Line

Composite Plate Duct Processing Equipment

Flange Machines Series

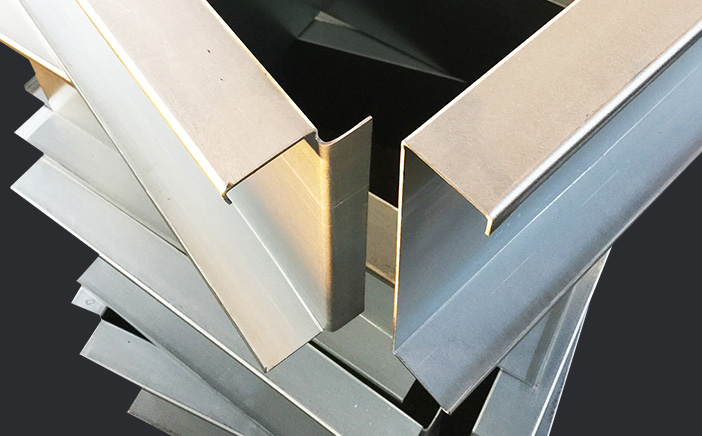

Pittsburgh Lock Forming Machine Series

Angle Iron Flange Processing Equipment

Square Duct Forming Auxiliary Equipment

Round Duct Processing Equipment

Damper Processing Equipment

Fan Coil Equipment

Cable Tray Production Line

Fire Hose Production Line

Comprehensive Support and Hanger Processing Equipment

-

Application

-

Services

-

News

-

COORIG

-

Contact

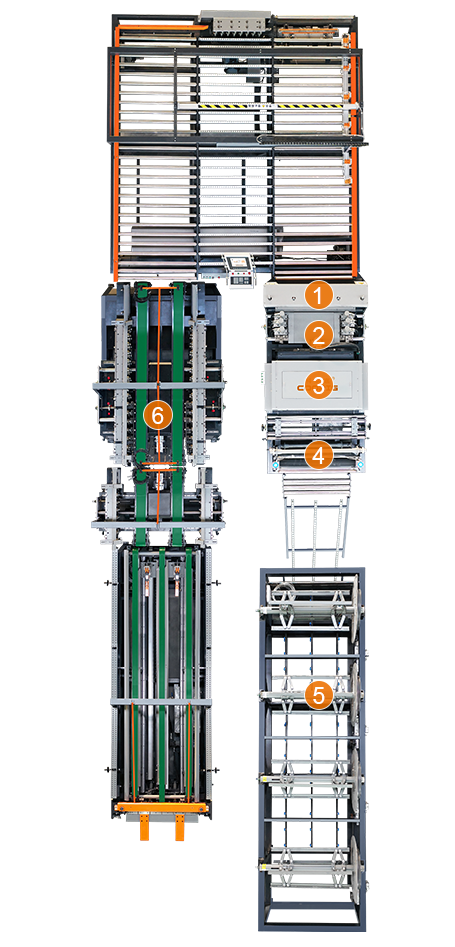

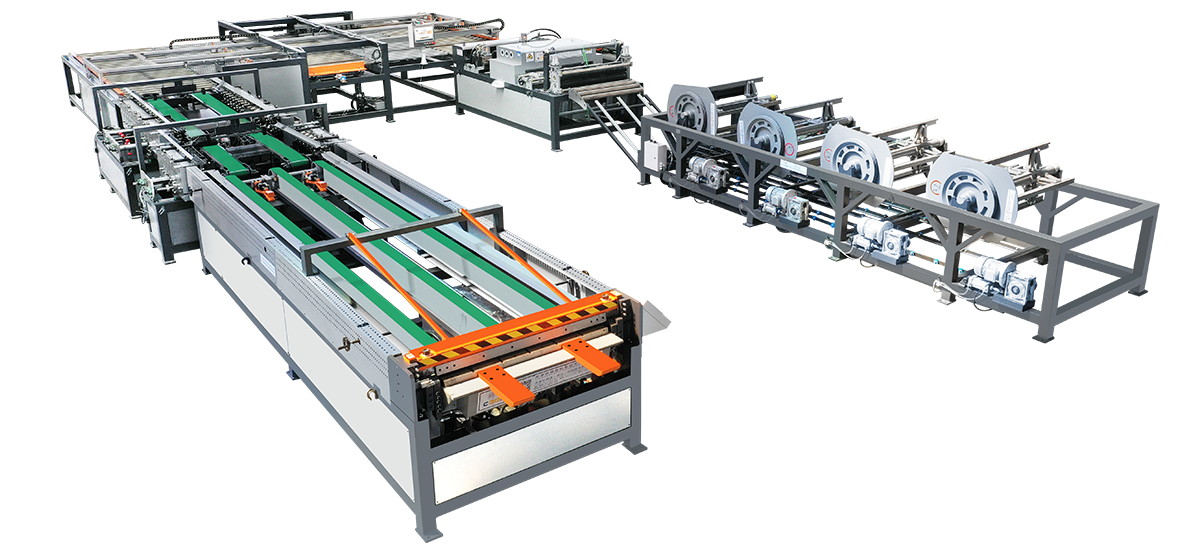

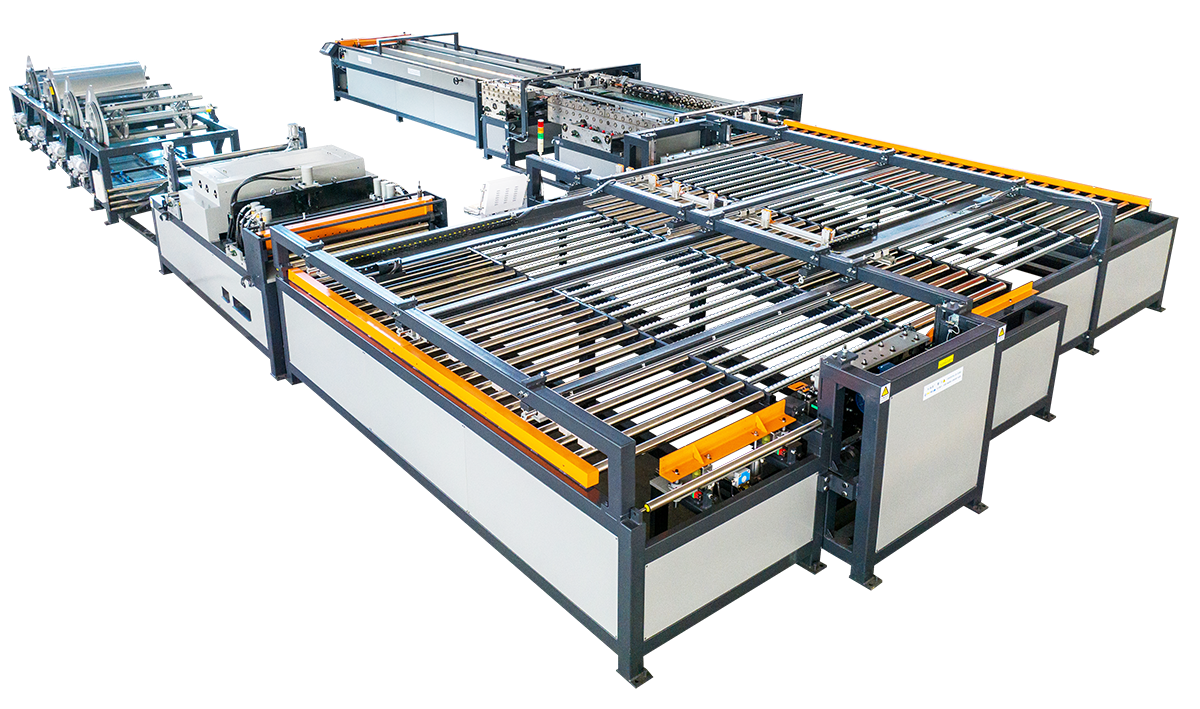

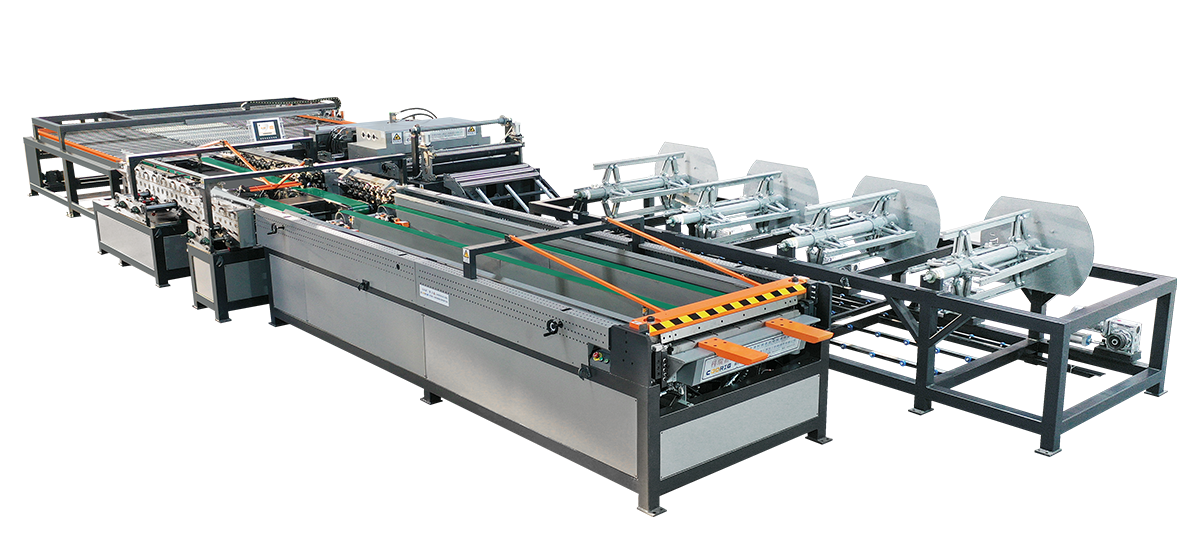

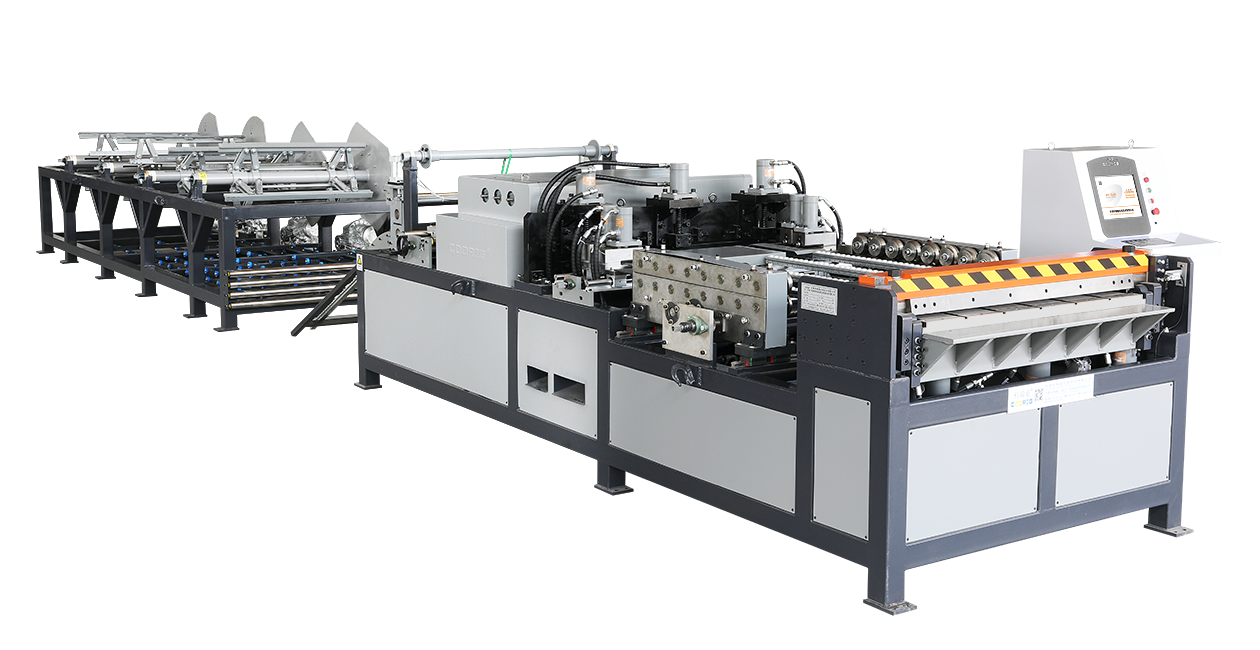

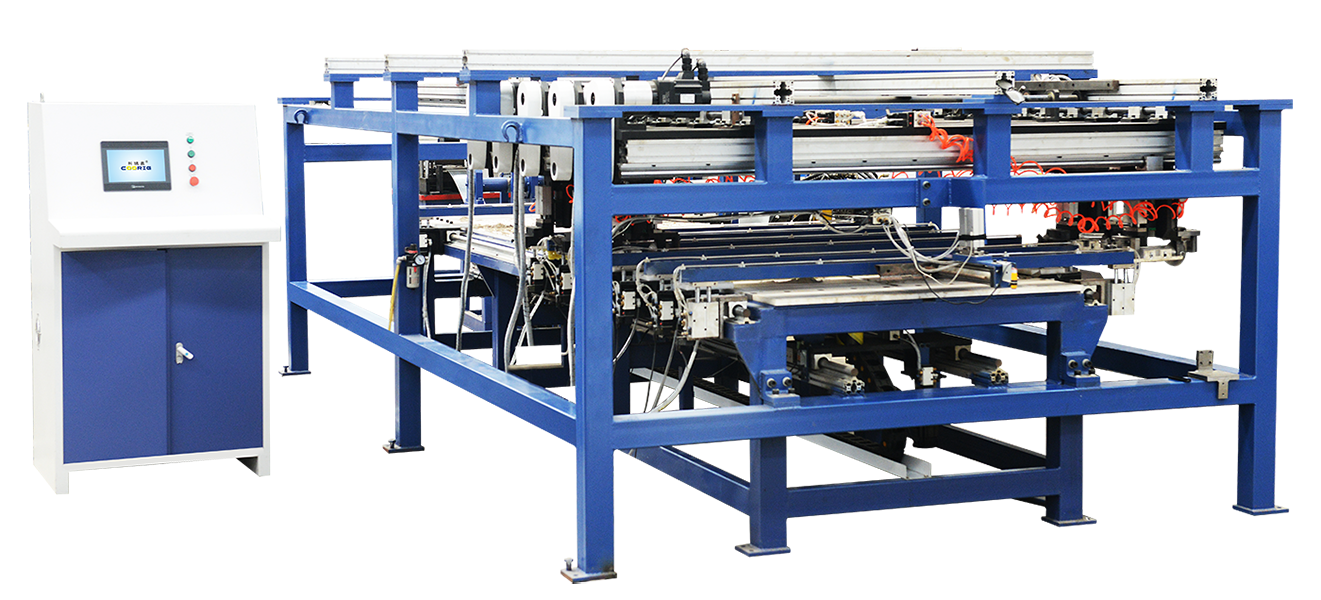

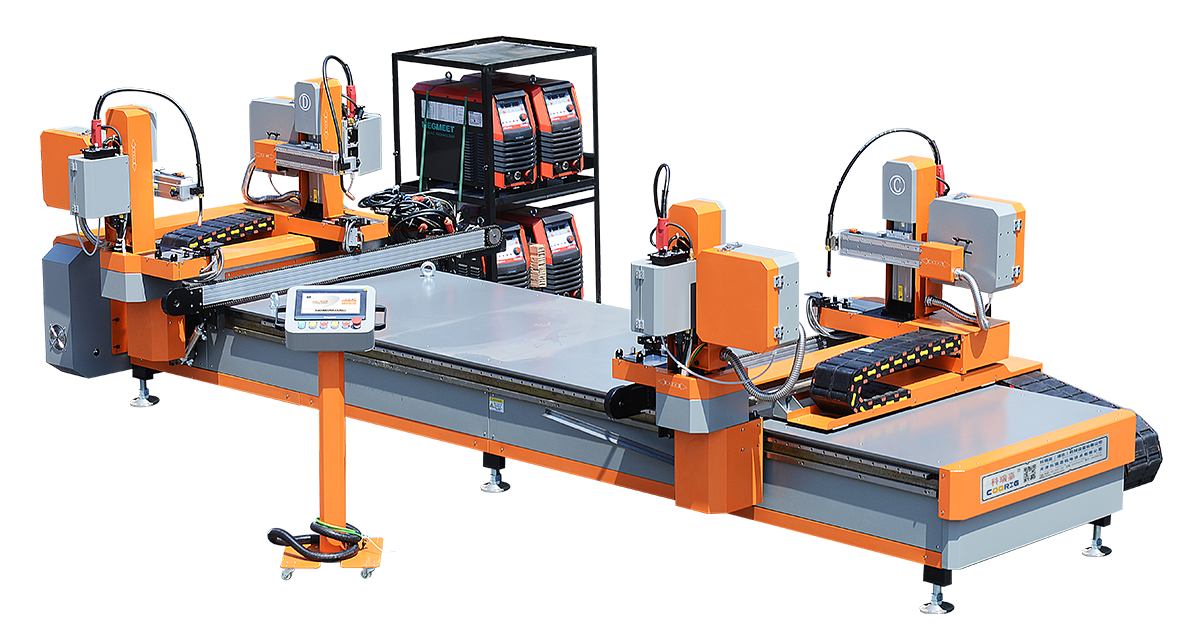

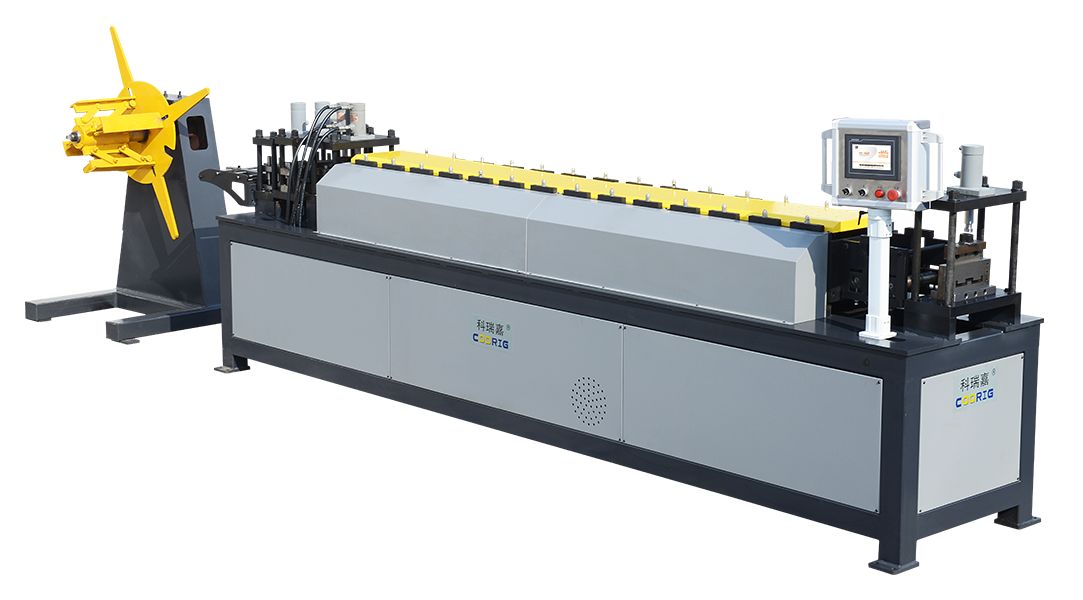

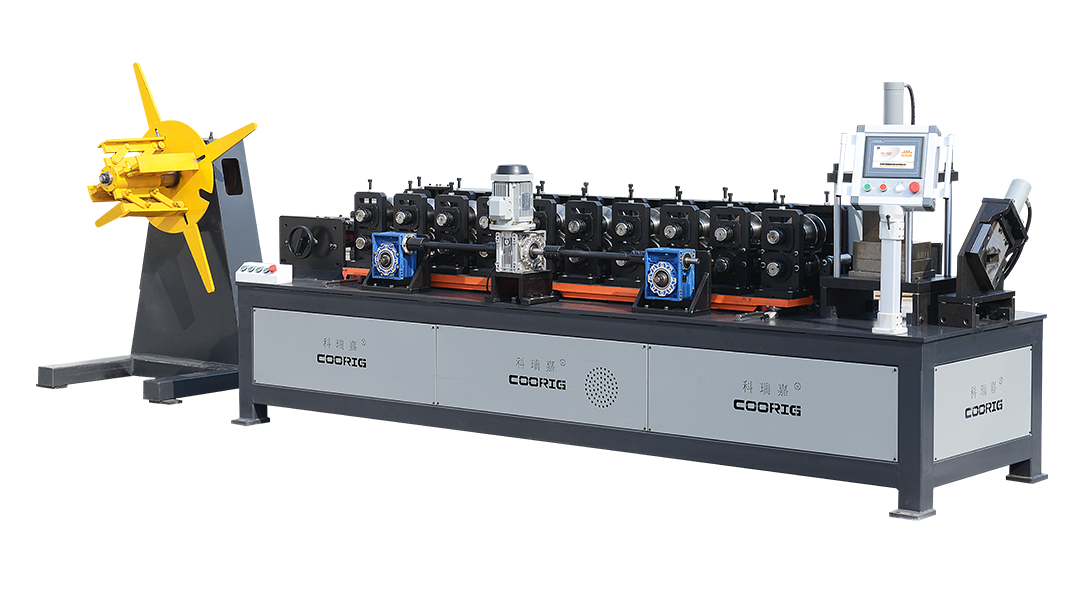

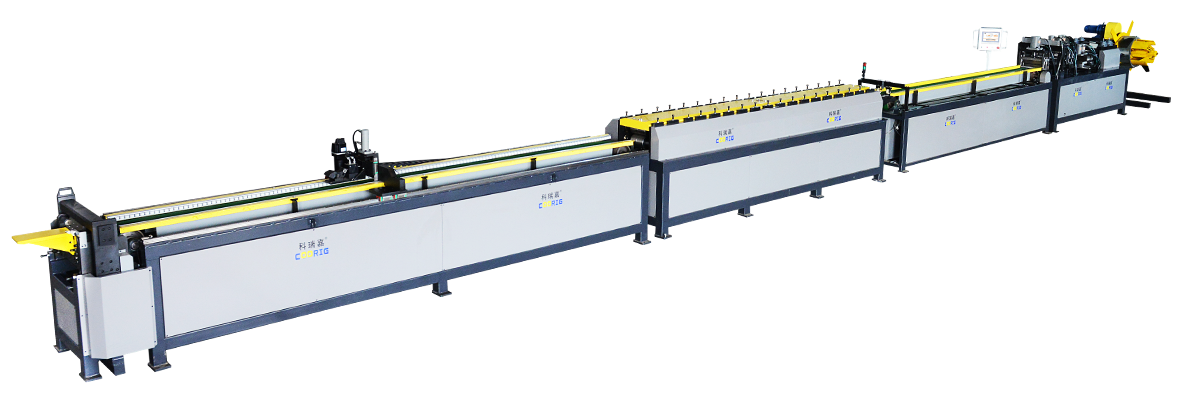

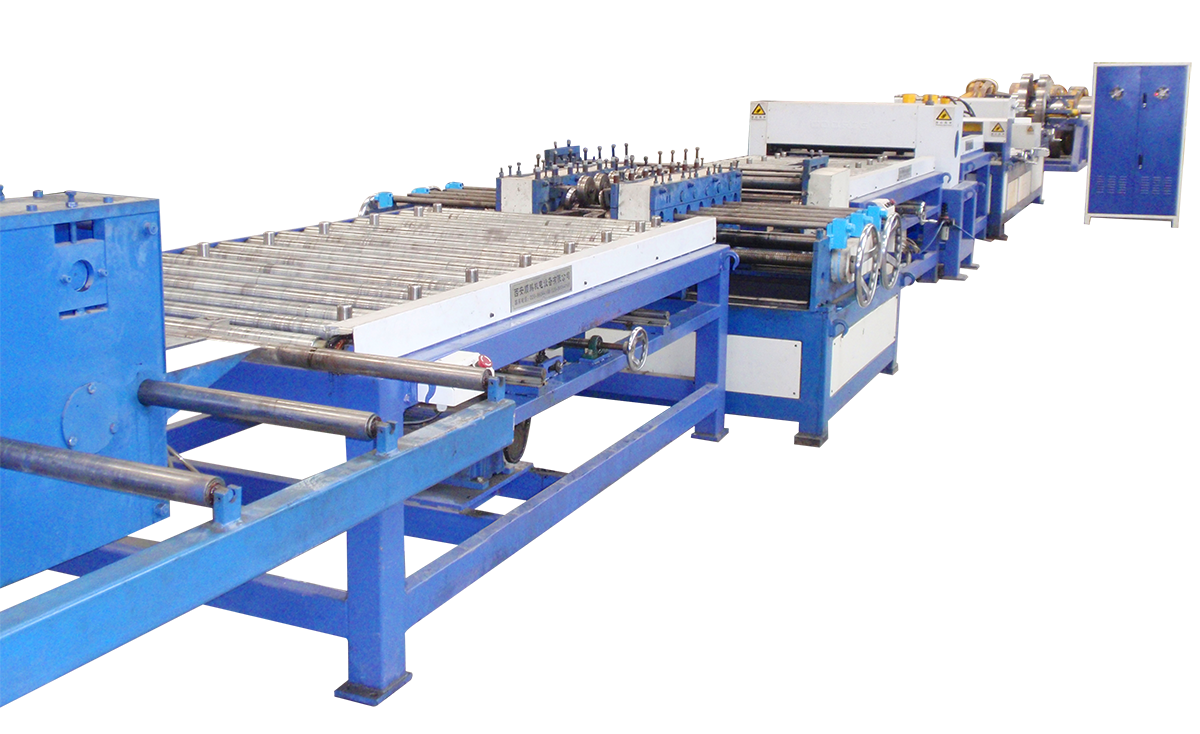

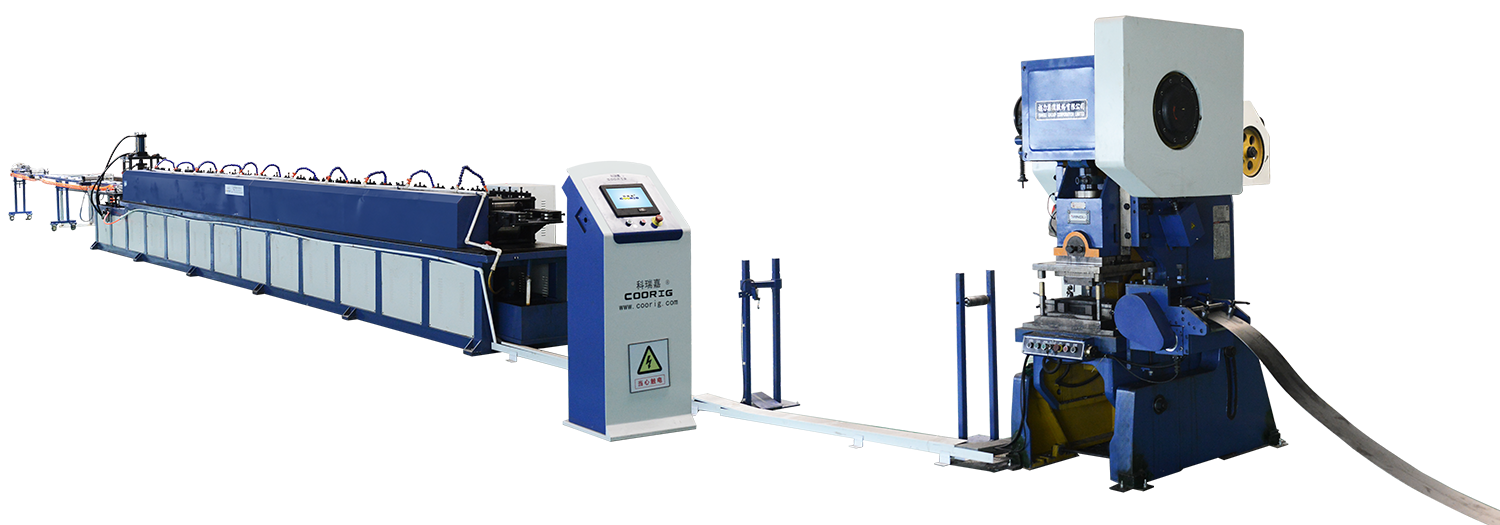

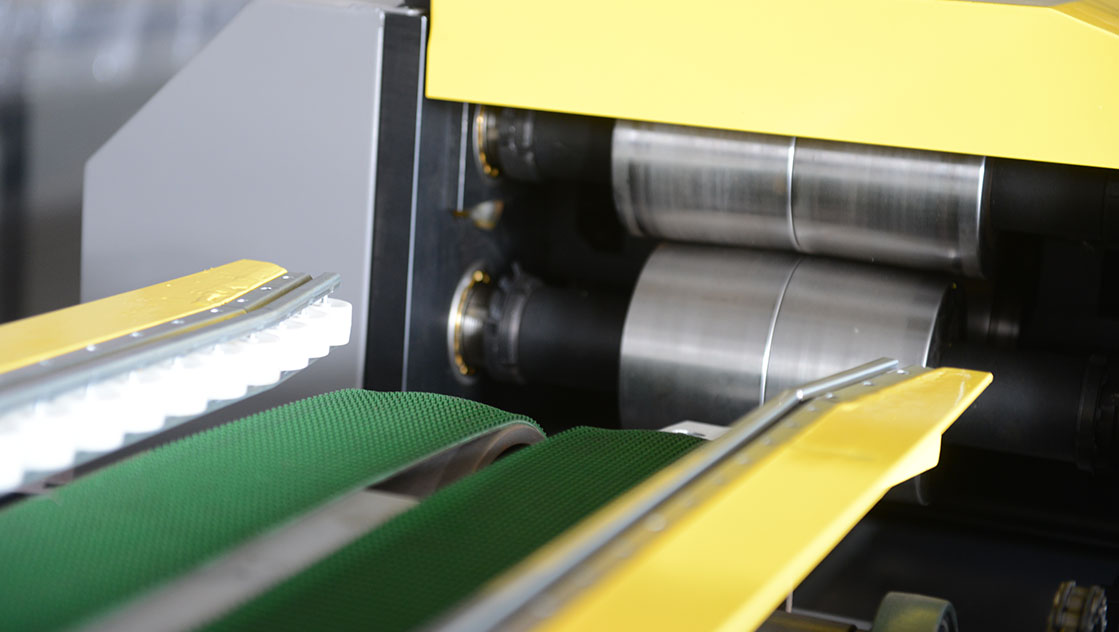

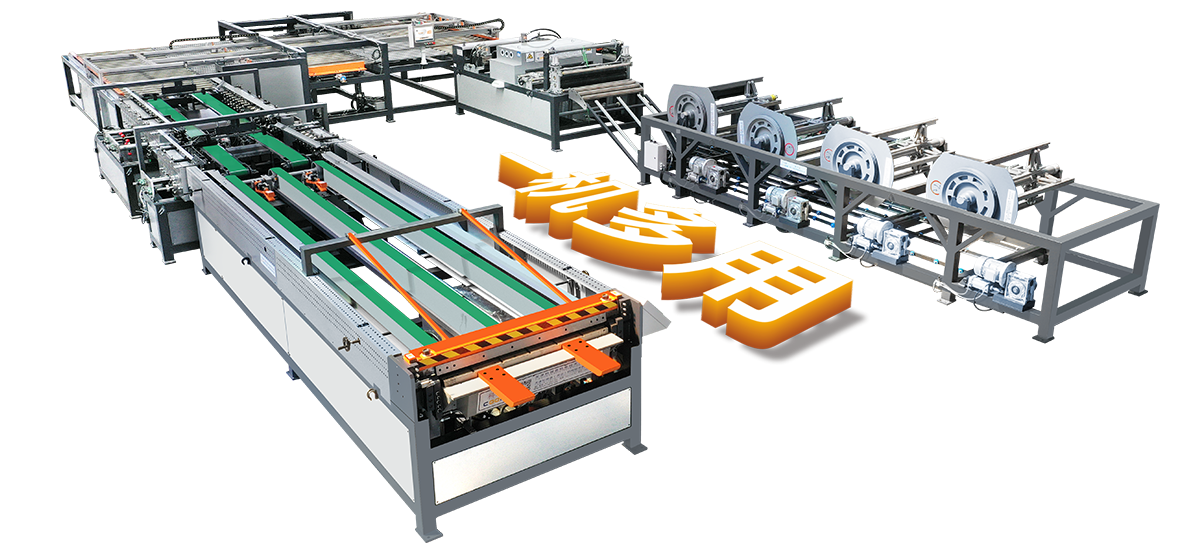

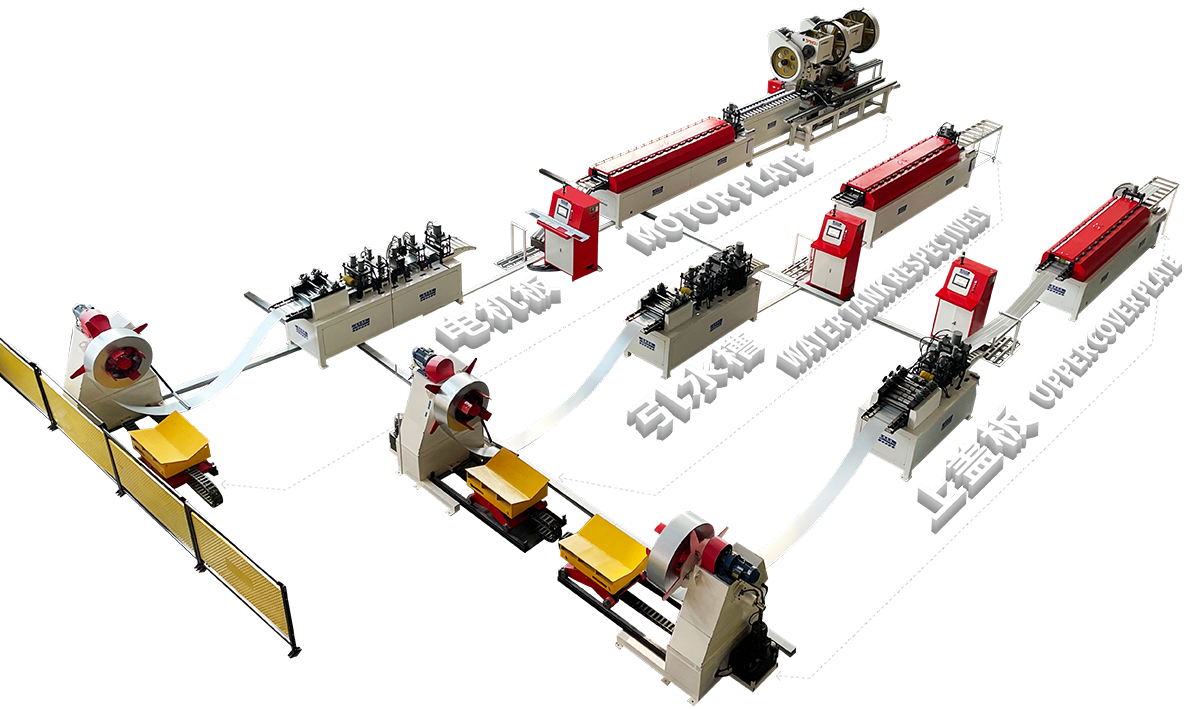

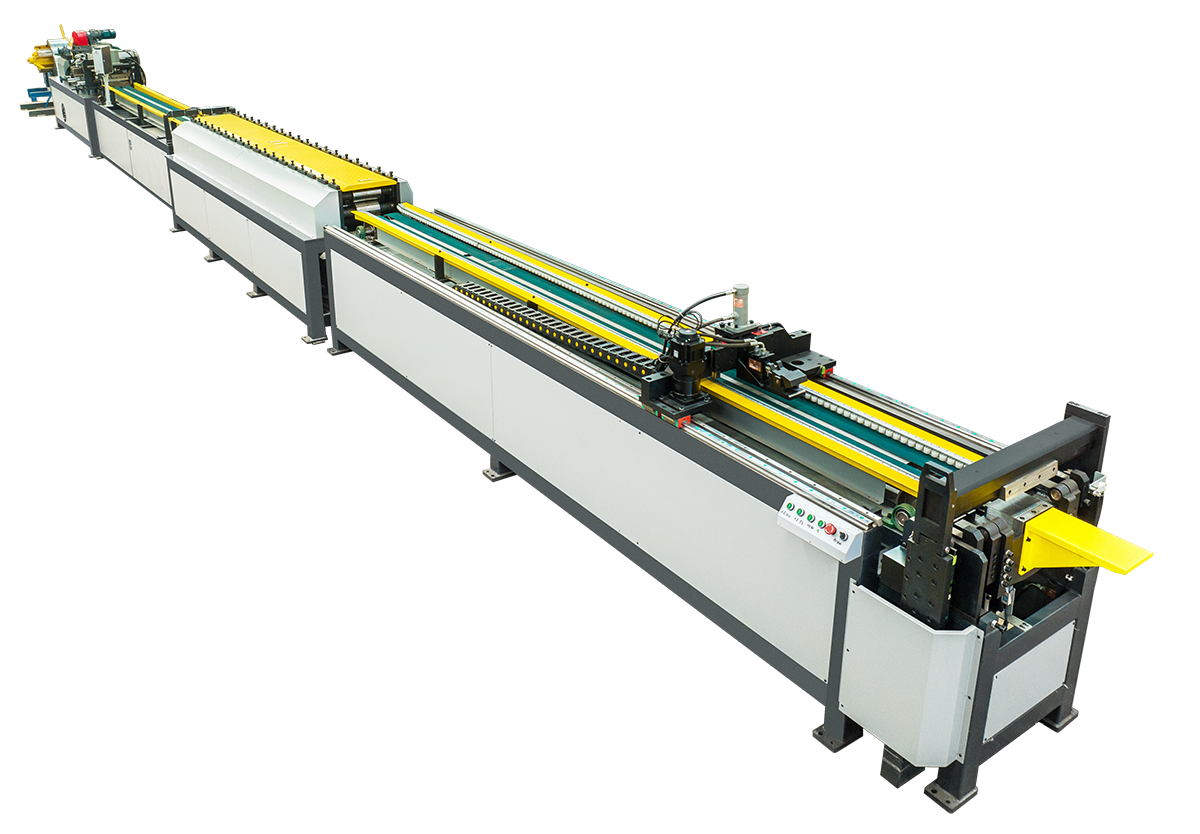

Automatic Damper Frame Production Line

Fully functional, can complete all the holes and cutting corners on the housing of volume damper, change the traditional processing methods by punch machine manually, improve production efficiency, ensure the products consistency;Reduce labor, just need two workers to operate the machine; You can also input various specifications, not only can make the "口" type, you can also complete a variety of shapes,such as the “L” type and monolithic type etc according to the actual situation of customers; The same machine can complete the volume damper forming for TDF flange and angle steel flange, fully realized that one machine for multi functions.

BASIC CONFIGURATION

1. One electric material feeding de-coiler;

2. One switch holder ;

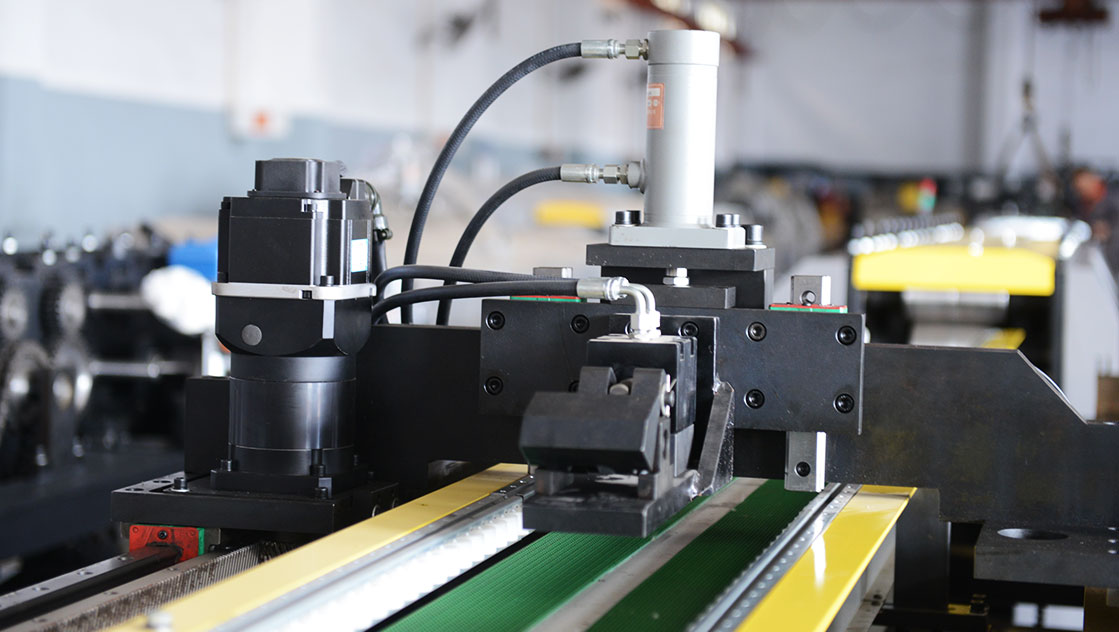

3. One servo leveling, punching and shearing host;

4. One transferring platform;

5. One flange forming machine;

6. One servo feeding and folding platform;

7. A set of hydraulic system;

8. A CNC system.

FUNCTION

It mainly completes the processing of fire damper, pressure regulating damper,

damper outer frame and the blanking of smoke exhaust damper.

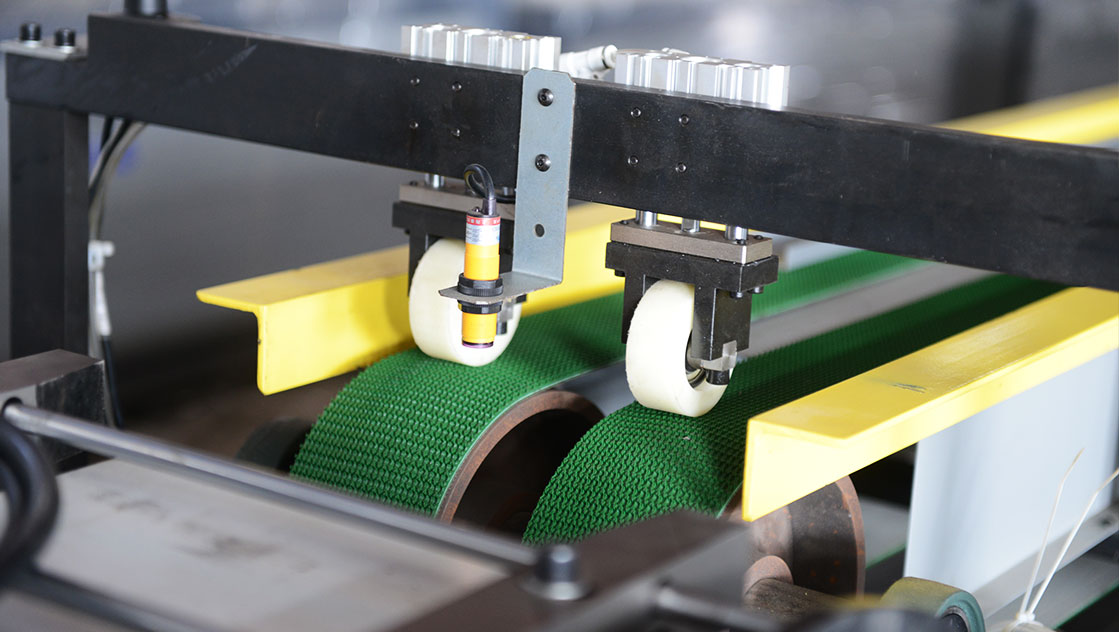

The production line can automatically complete uncoiling, leveling, notching, punching,

shearing, flange forming (including TDF flange 35 and angle iron flange 30, 40, 50),

square folding and forming automatically.

BASIC CONFIGURATION

|

NO. |

Model |

Thickness

|

Max sheet |

Max feeding |

Power |

Dimensions |

Max |

|

5002

|

BPL-220 | 1.5-2.0 | 220 | 6 | 9.5 | 5500x1000x1500 | 1500 |

|---|---|---|---|---|---|---|---|

|

The equipment appearance, configuration and technical parameters are for reference only, the actual products shall prevail.

|

|||||||

More Product Information

-

- HEADQUARTERS

- TIANJIN COORIG TECHNOLOGY CO.,LTD

- Add: Jinghai Developing Zone of Tianjin, China

- Tell: +86 022-68676316 / 68676317 / 68676318

- E-mail: forest@coorig.com

- PRODUCTION BASE

- HUBEI COORIG TECHNOLOGY CO., LTD

- Add: Fengridadao,Developing Zone of Chongyang,Hubei, China

- Tell: +86 0715-3300166 / 3300566

- E-mail: forest@coorig.com

-

- Products

- Duct Forming Production Line

- Laser Cutting Machine Series

- Metal Insulation Pipe Production Line

- Composite Plate Duct Processing Equipment

- Flange Machines Series

- Pittsburgh Lock Forming Machine Series

- Angle Iron Flange Processing Equipment

- Square Duct Forming Auxiliary Equipment

- Round Duct Processing Equipment

- Damper Processing Equipment

- Fan Coil Equipment

- Cable Tray Production Line

- Fire Hose Production Line

- Comprehensive Support and Hanger Processing Equipment

- Services

- After-Sale Service

- Service Network

- Application

- Customer Site

- Video Center

-

WeChat Official Account

-

Mobile Browsings