-

Products

-

Duct Forming Production Line

-

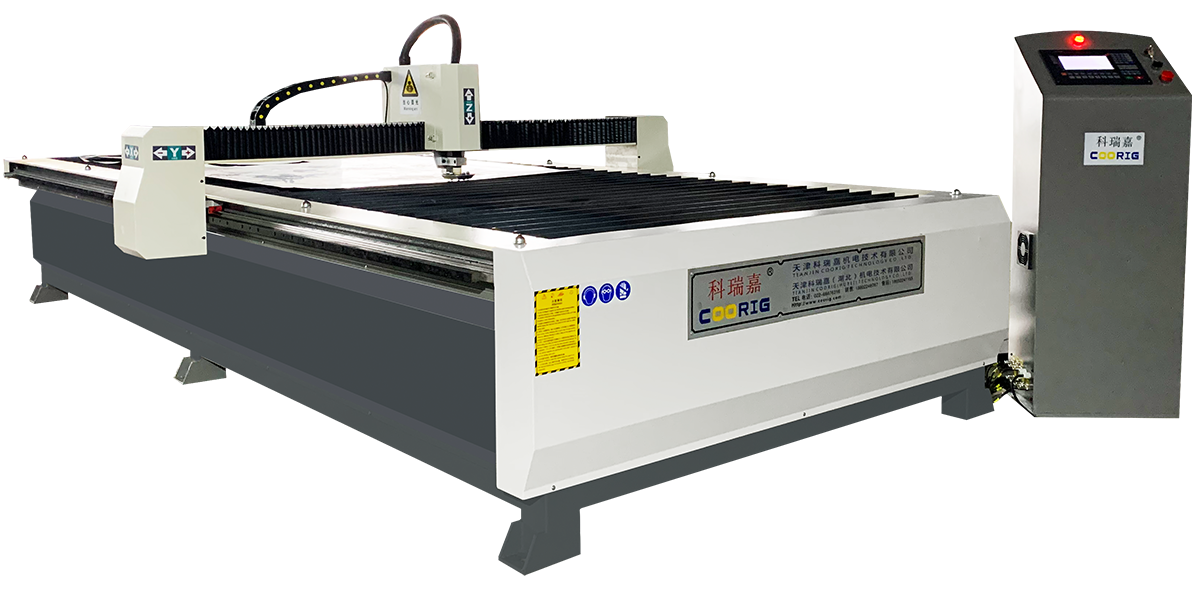

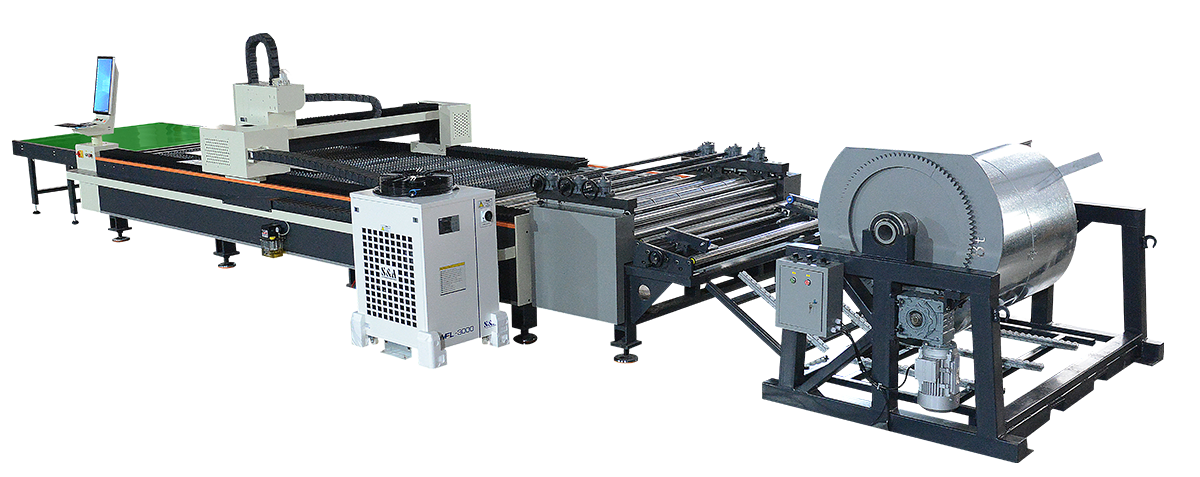

Laser Cutting Machine Series

-

Metal Insulation Pipe Production Line

-

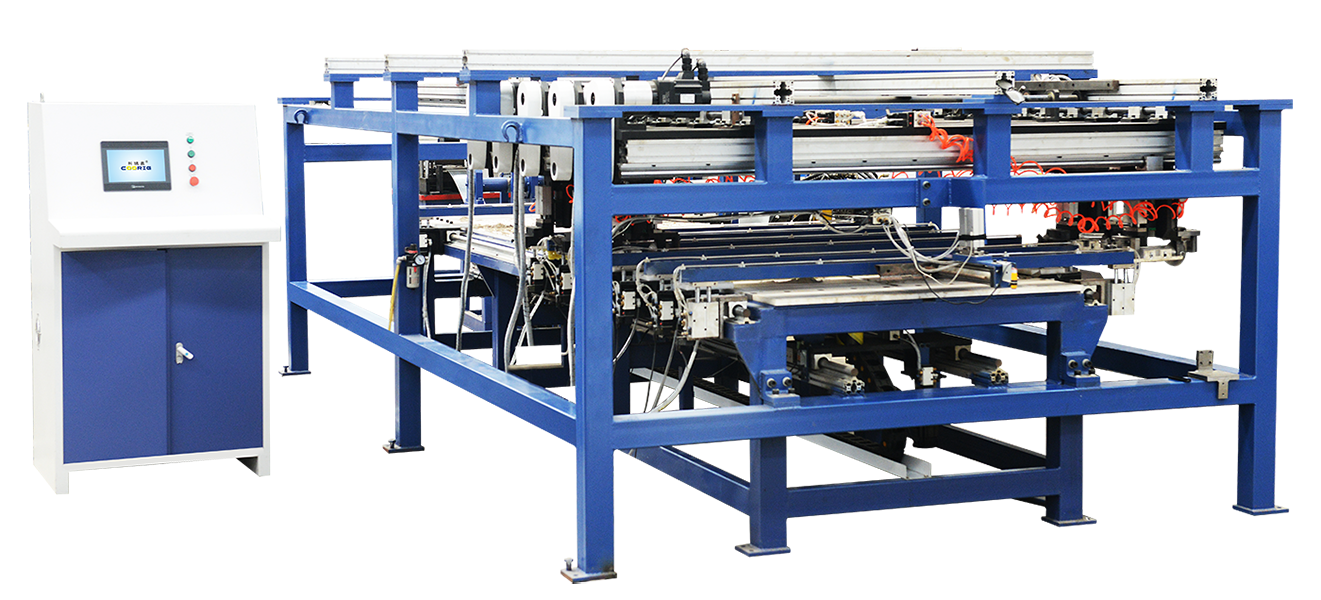

Composite Plate Duct Processing Equipment

-

Flange Machines Series

-

Pittsburgh Lock Forming Machine Series

-

Angle Iron Flange Processing Equipment

-

Square Duct Forming Auxiliary Equipment

-

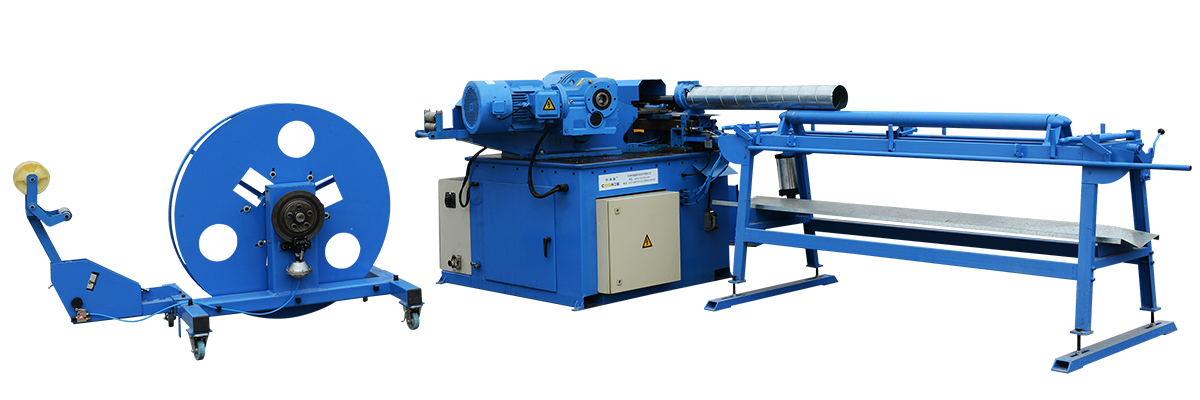

Round Duct Processing Equipment

-

Damper Processing Equipment

-

Fan Coil Equipment

-

Cable Tray Production Line

-

Fire Hose Production Line

-

Comprehensive Support and Hanger Processing Equipment

-

-

Products

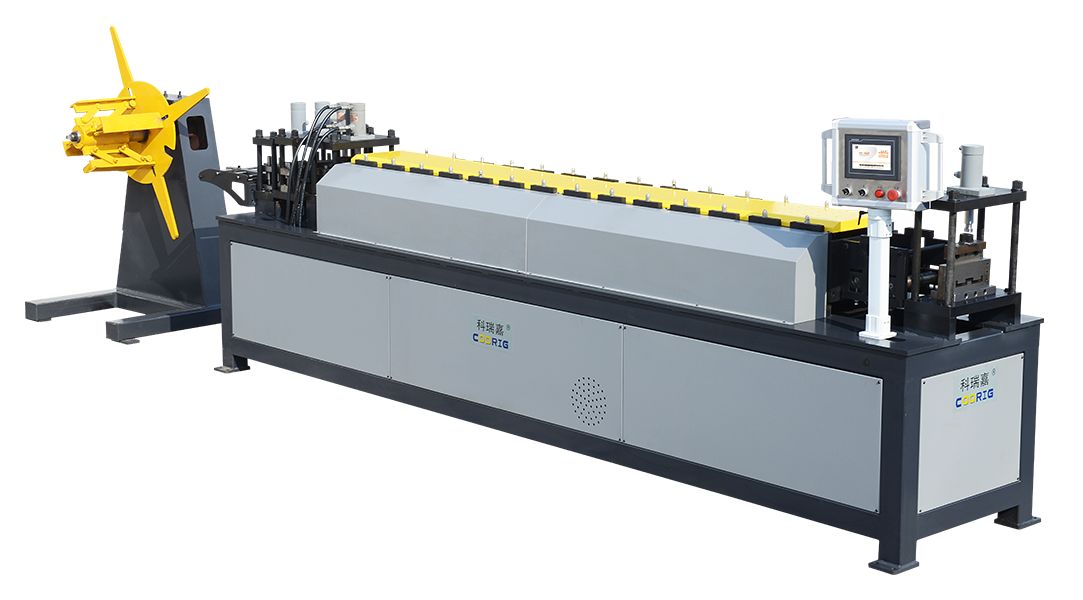

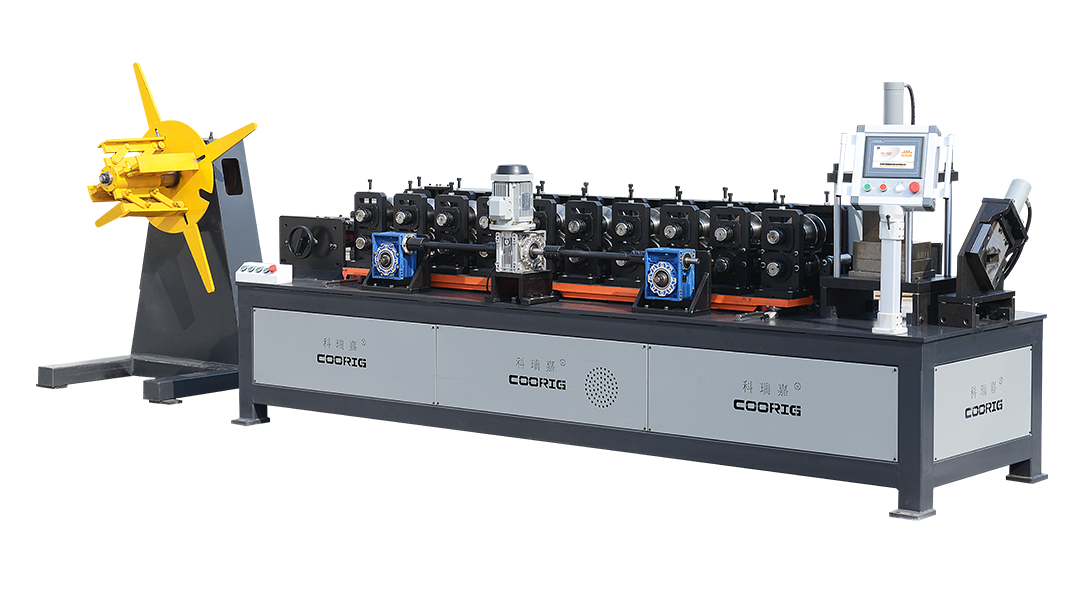

Duct Forming Production Line

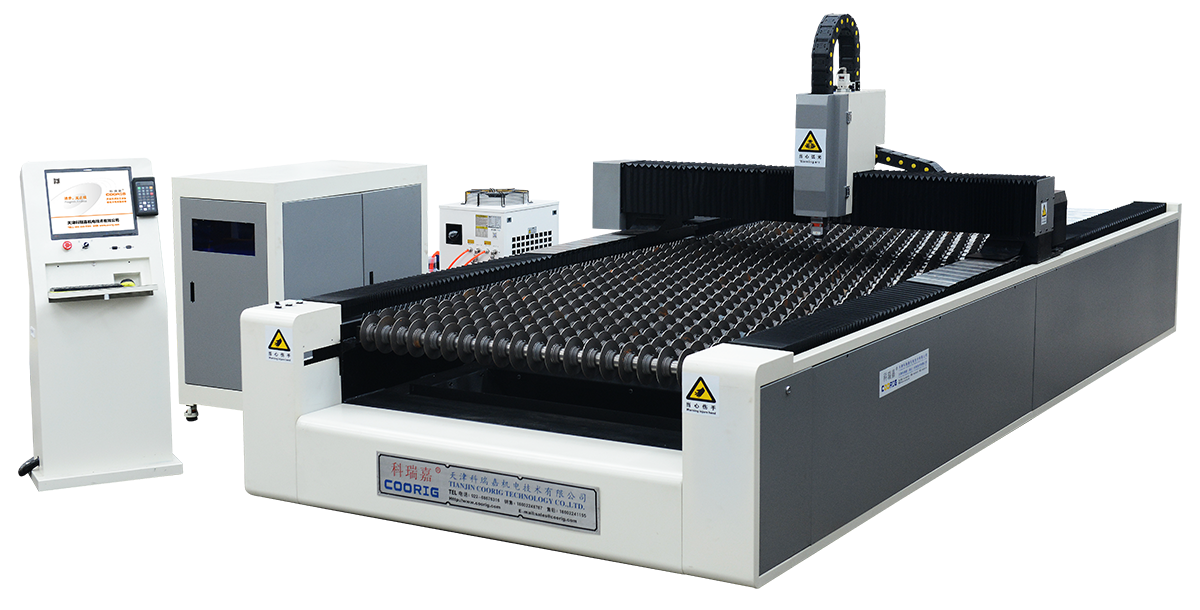

Laser Cutting Machine Series

Metal Insulation Pipe Production Line

Composite Plate Duct Processing Equipment

Flange Machines Series

Pittsburgh Lock Forming Machine Series

Angle Iron Flange Processing Equipment

Square Duct Forming Auxiliary Equipment

Round Duct Processing Equipment

Damper Processing Equipment

Fan Coil Equipment

Cable Tray Production Line

Fire Hose Production Line

Comprehensive Support and Hanger Processing Equipment

-

Application

-

Services

-

News

-

COORIG

-

Contact

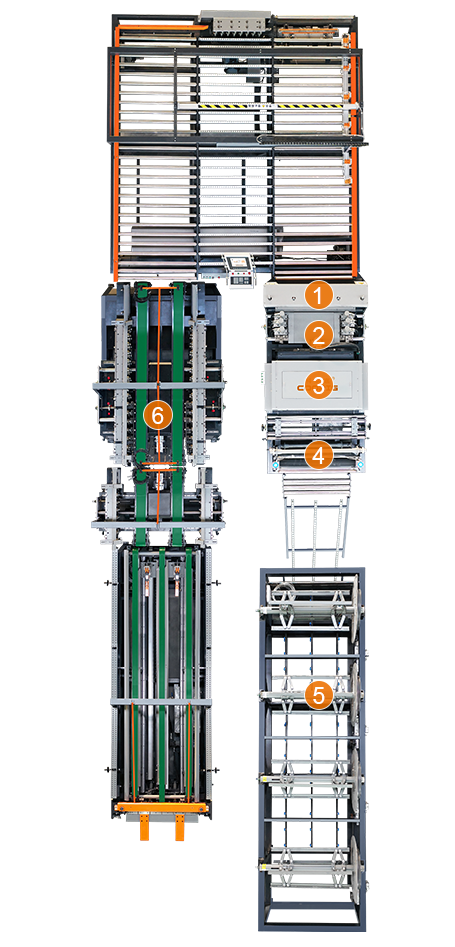

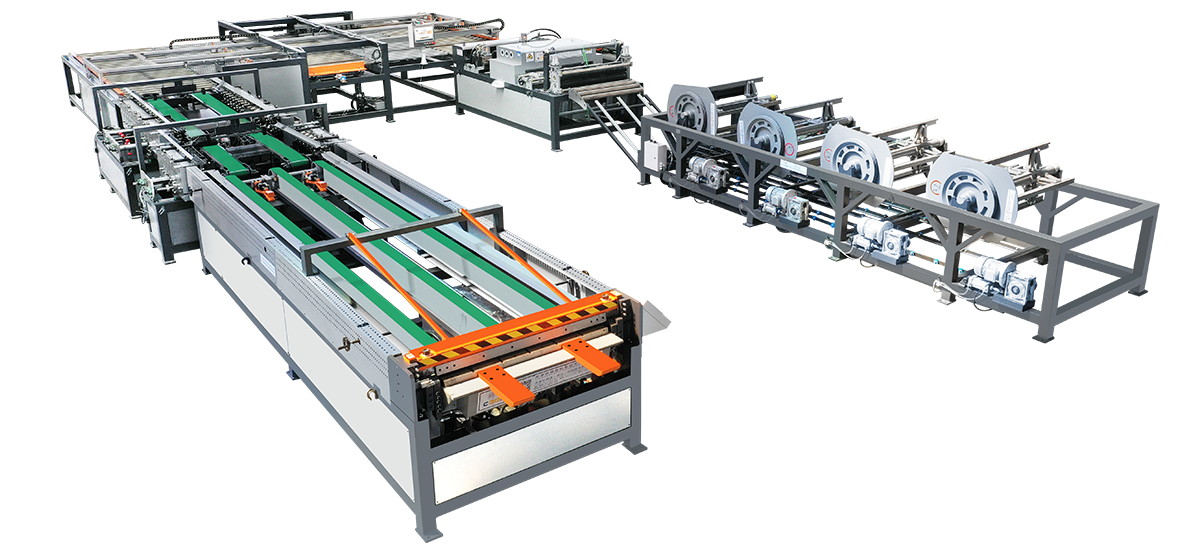

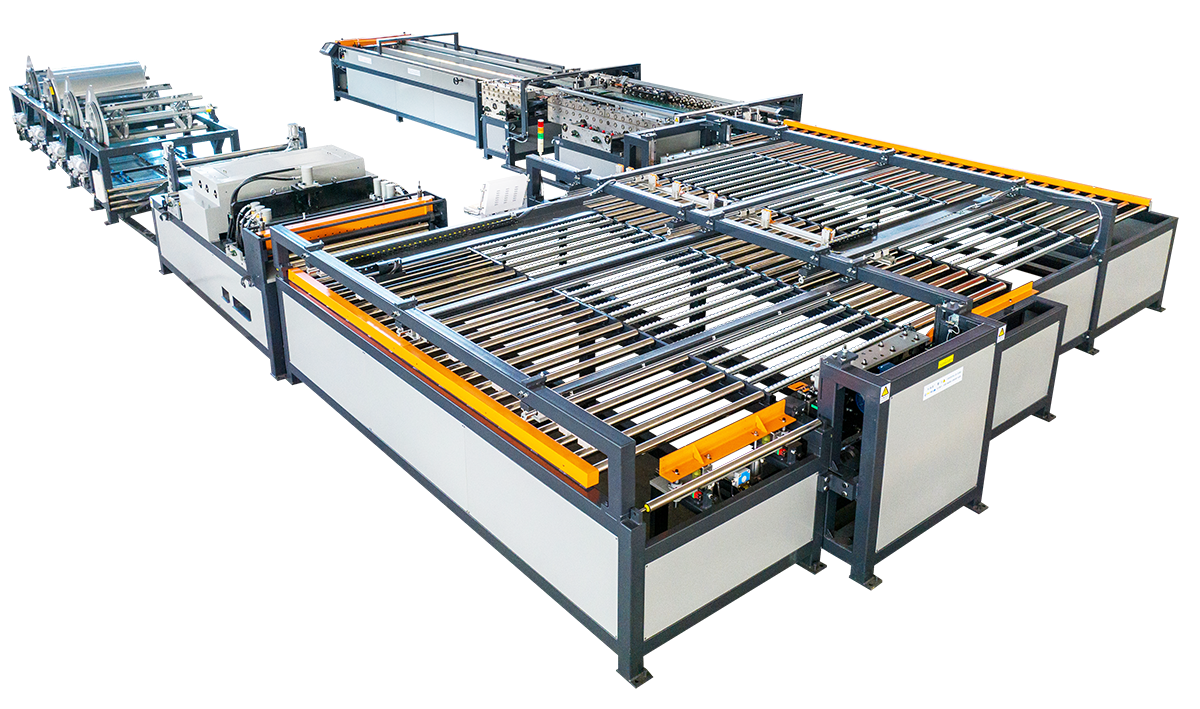

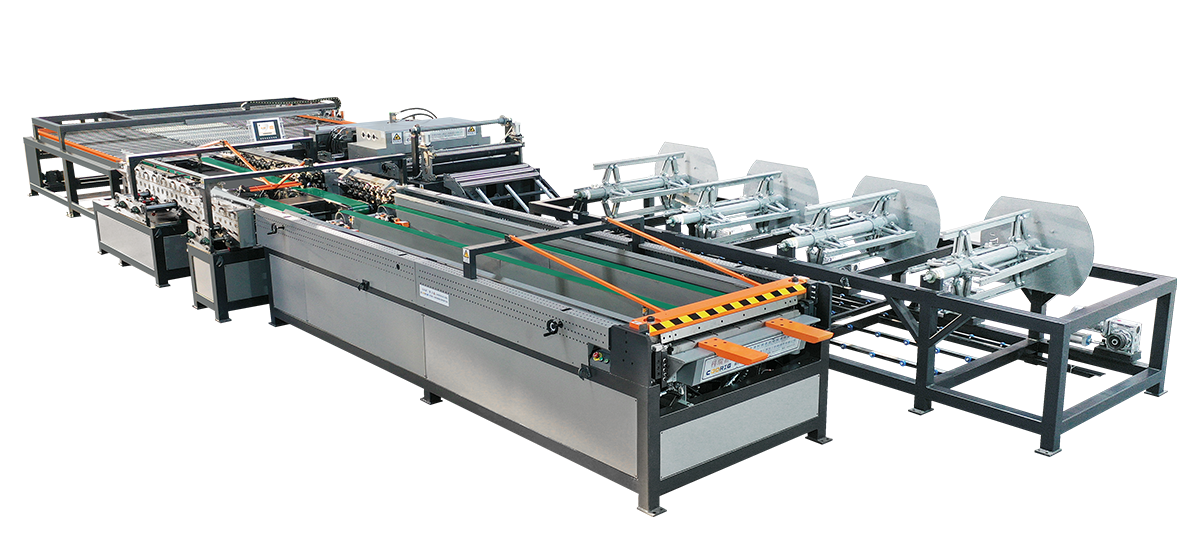

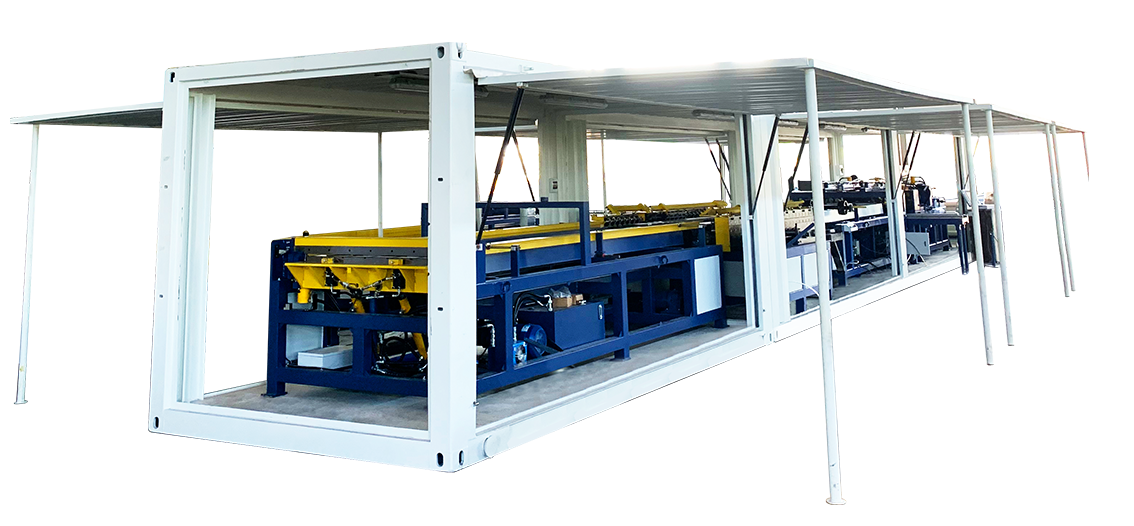

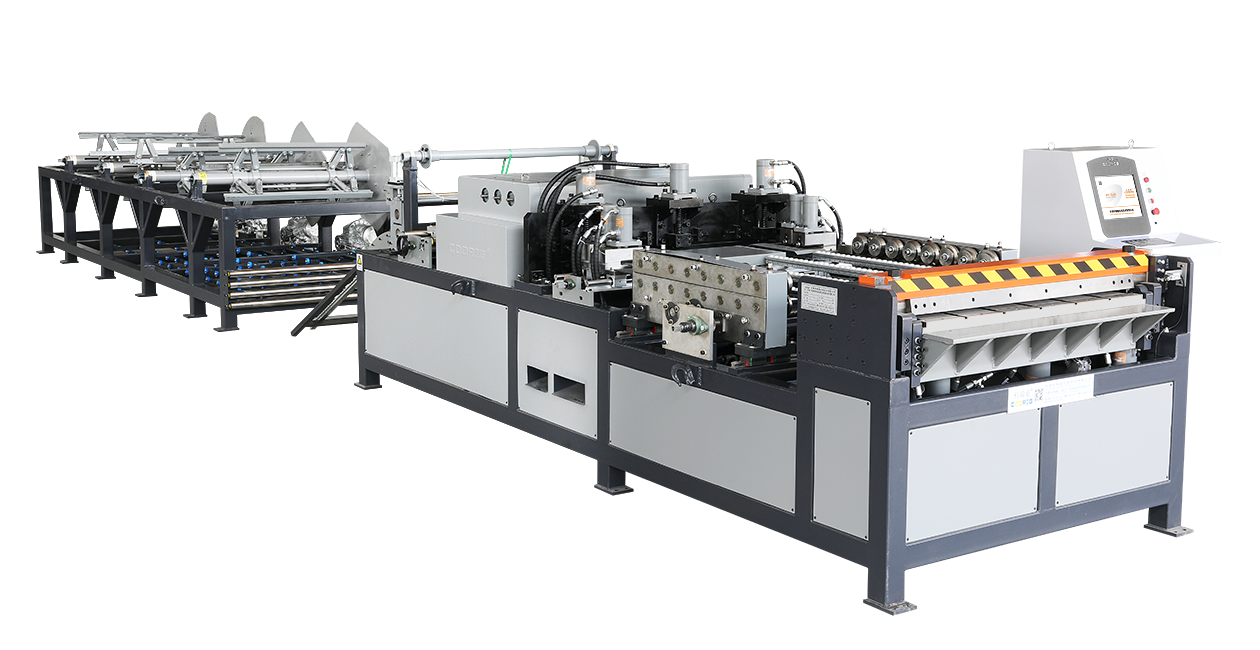

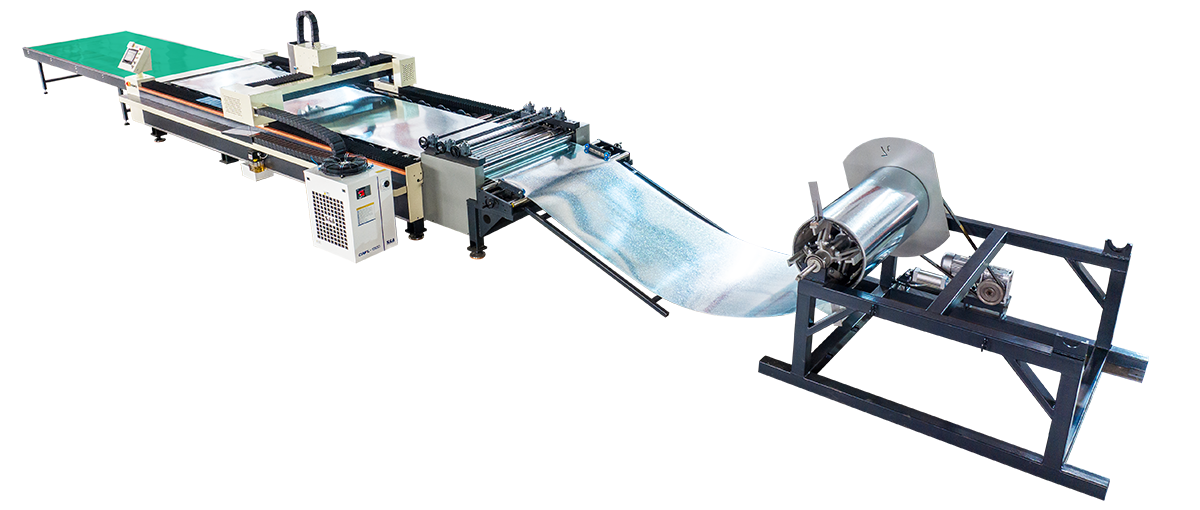

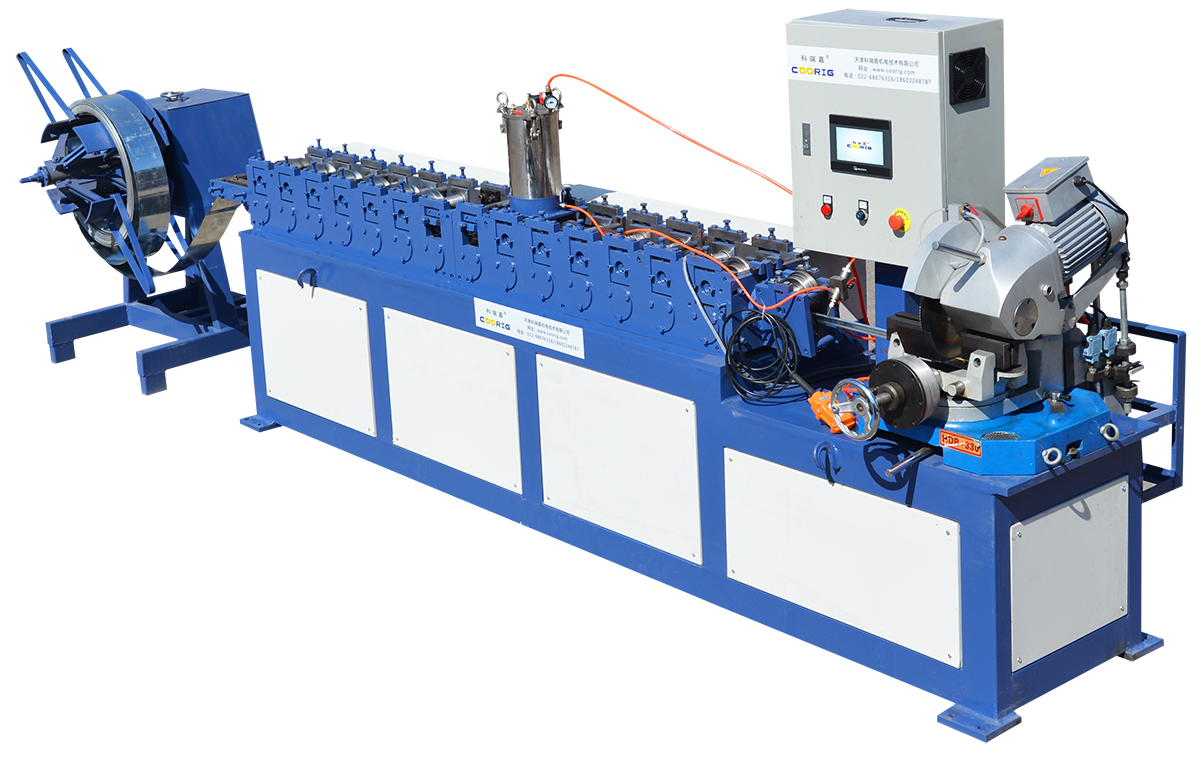

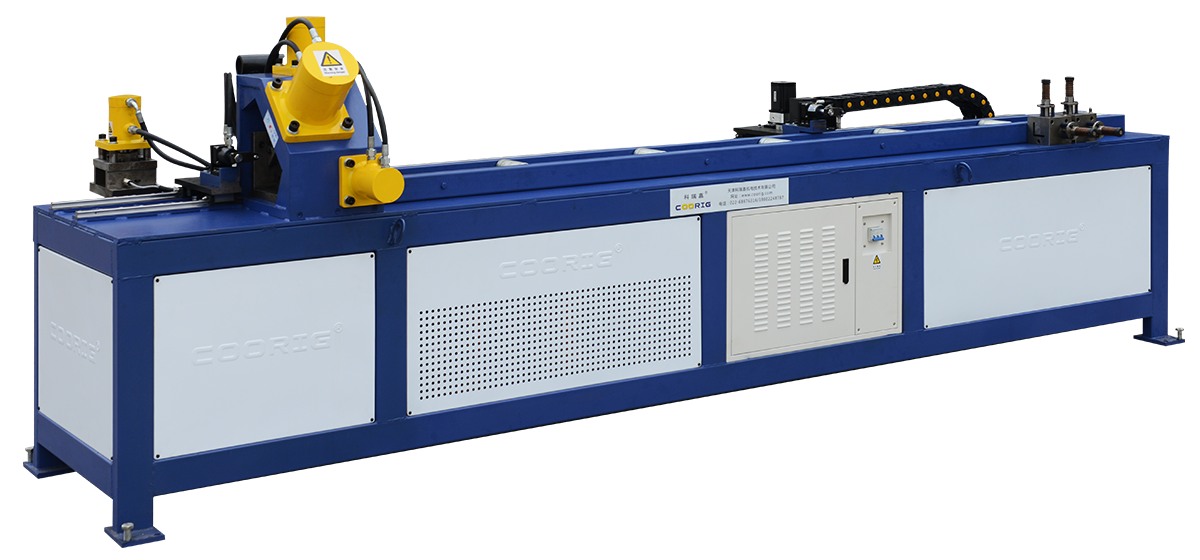

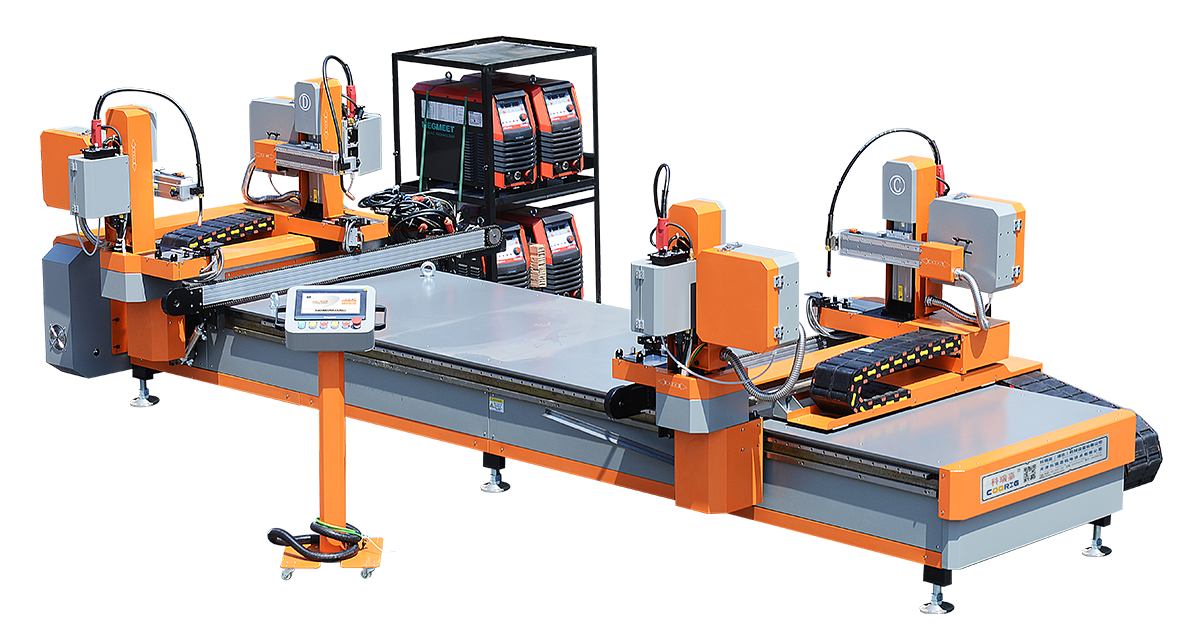

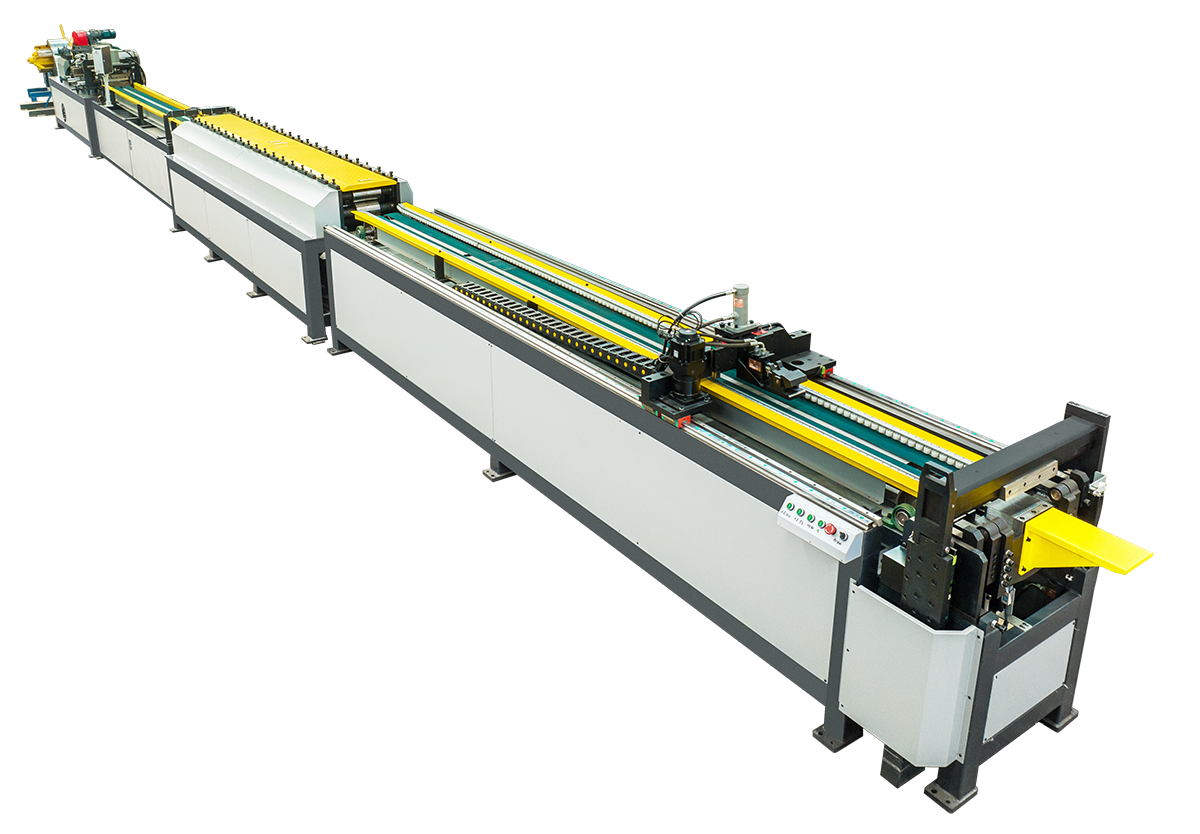

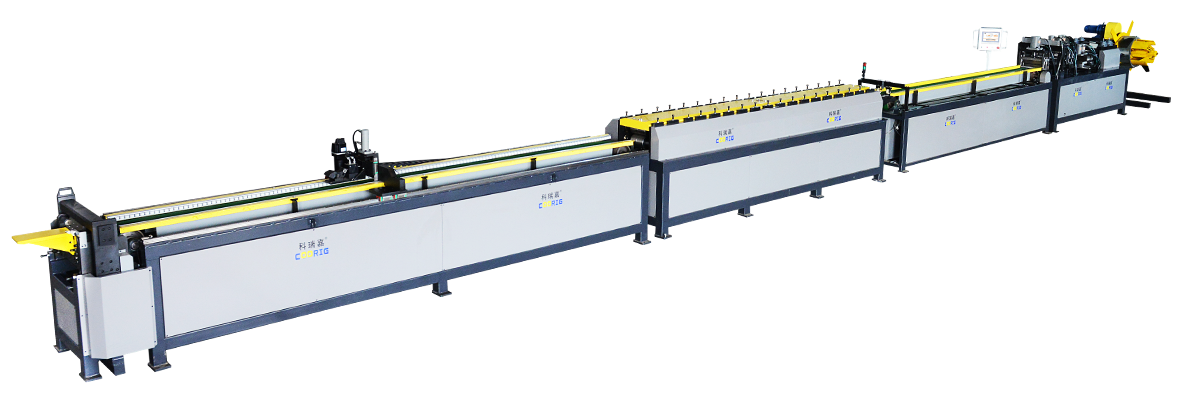

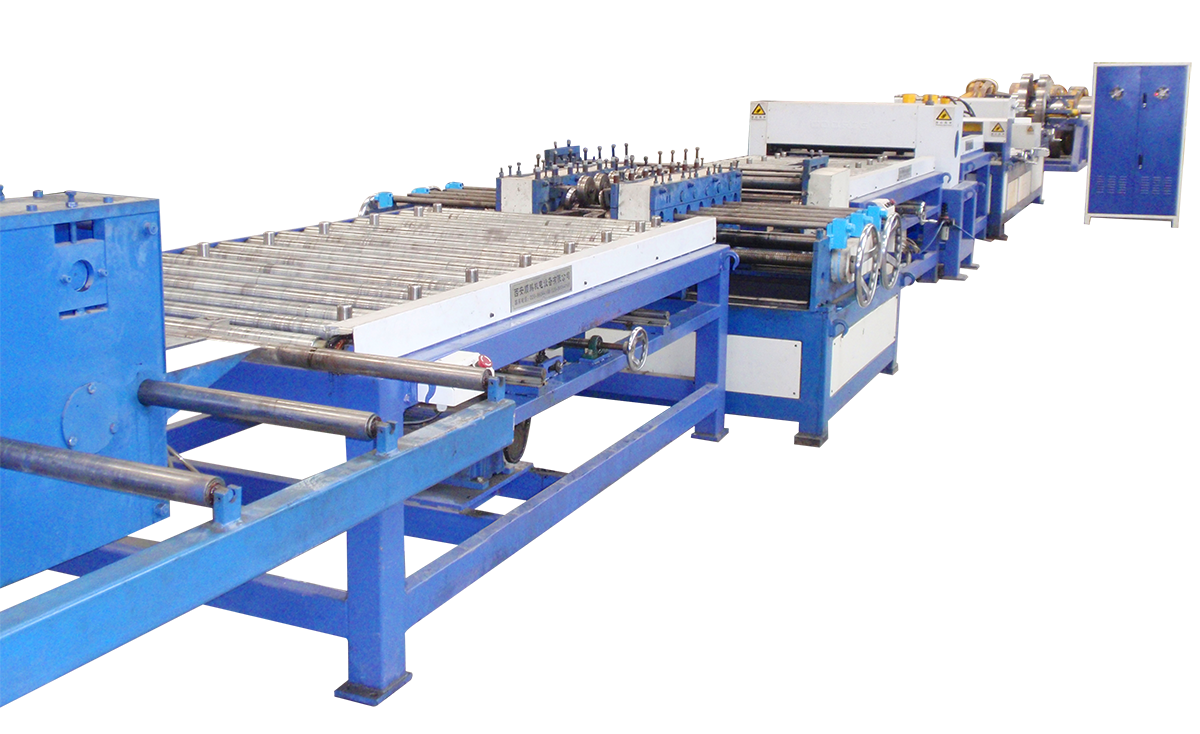

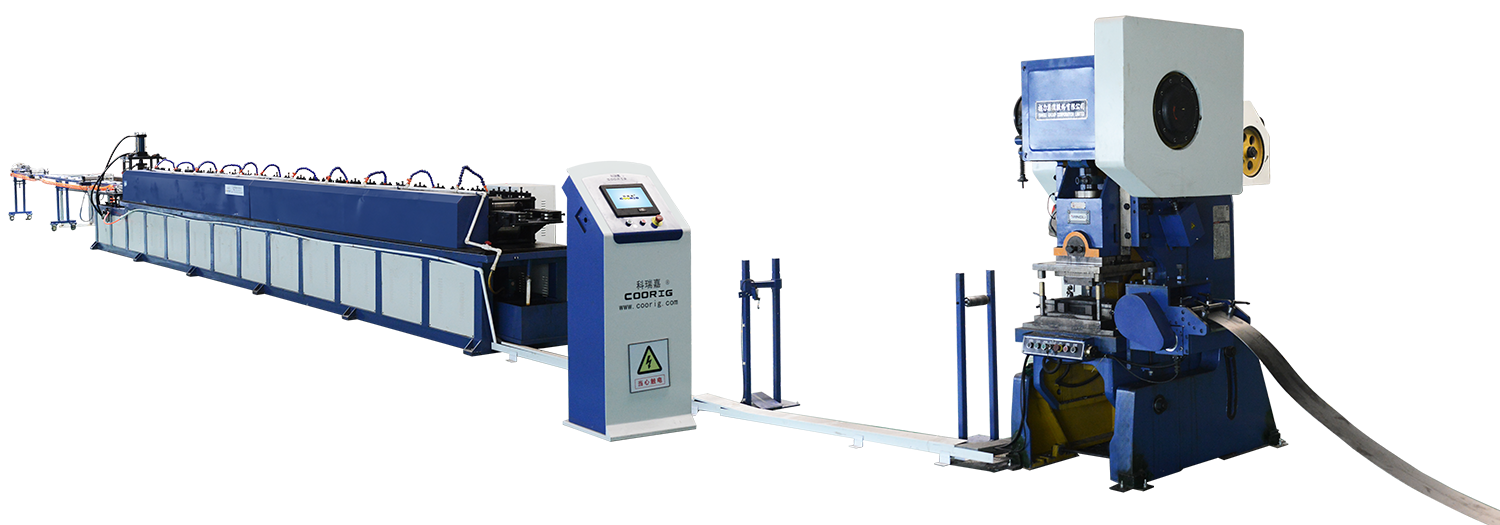

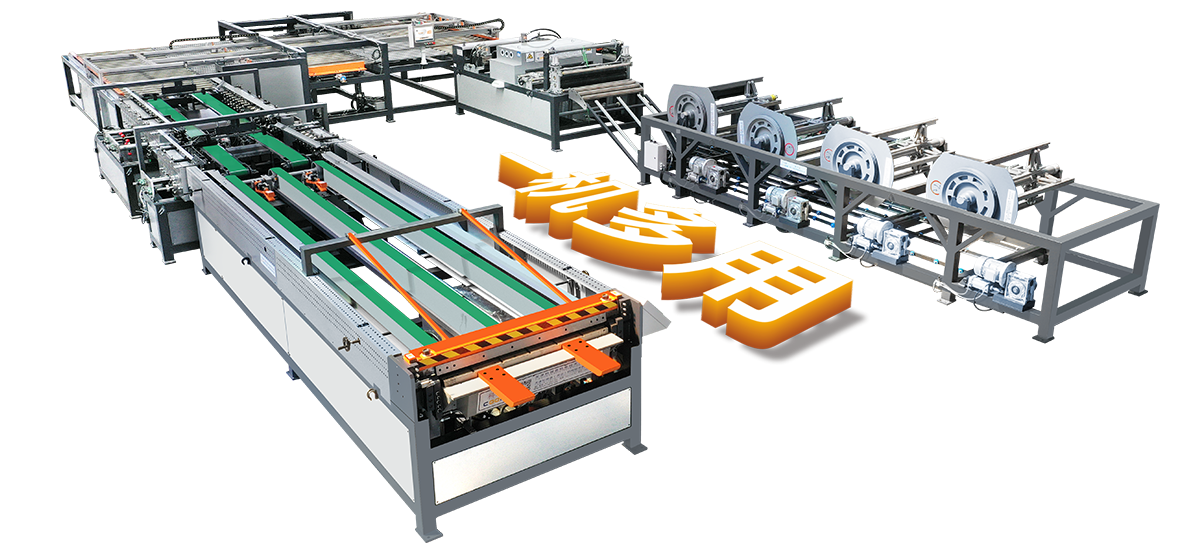

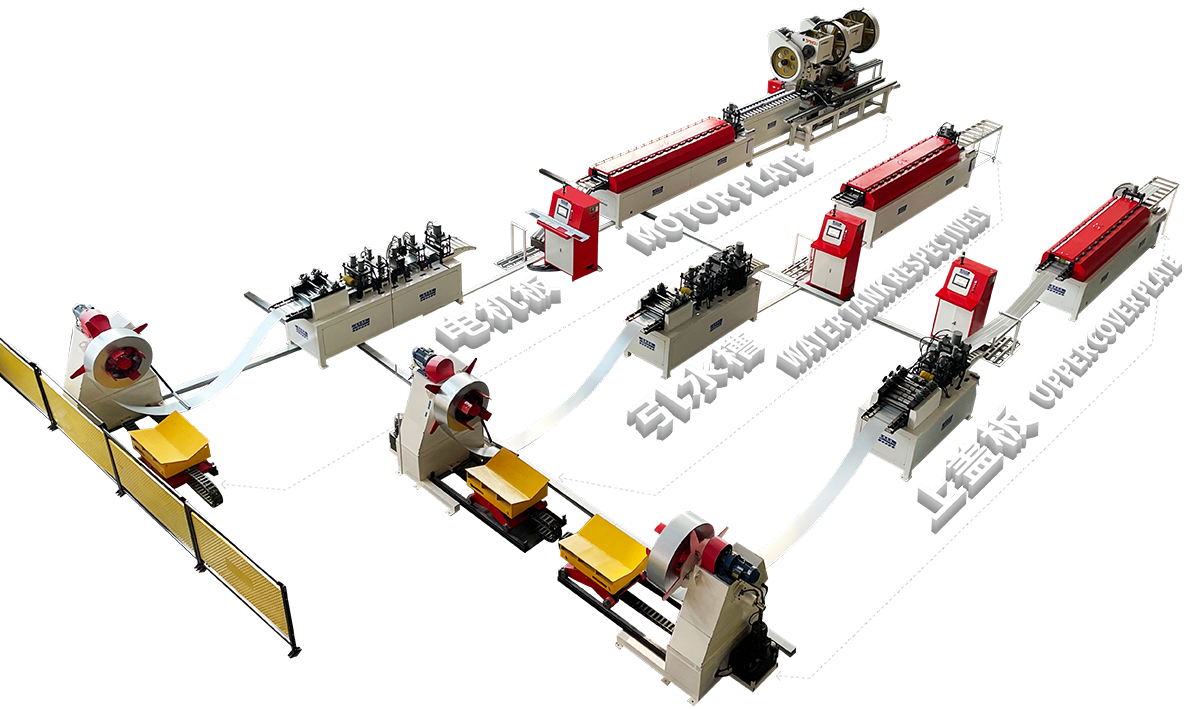

Fully Automatic Pipe Cutting Production Line

Equipped with a fully automatic double head threading machine and a grooving machine, or used alone, it is mainly used for on-site processing, but also for semi-automatic processing of short pipes.

EQUIPMENT DESCRIPTION

1. This pipe cutting production line has basically realized intelligent automation and has fully automatic feeding and blanking functions. It adopts advanced CNC numerical control system to achieve a fully data-based production process for the pipe cutting production line, which can be connected to an assembly line for a fully automatic double head threading machine.

2. Multiple specifications, sizes, and quantities can be set at the same time, with a built-in tail cutting function to maximize material savings and improve efficiency.

3. The pipe cutting machine head is a multi group full gear gearbox, all connected to a CNC automatic oil lubrication system.

4. The unique fixture design can ensure that the product does not scratch or collide, and the delivery process is smooth.

5. The touch type man-machine interface is simple to operate and convenient to maintain.

6. The machine tool is equipped with a cooling system that uses a saw blade for cutting, and the sawdust and material head can be collected in a centralized manner.

7. The machine tool is equipped with an automatic alarm diagnosis system, which is easy to troubleshoot in a timely manner.

MAIN TECHNICAL DATA

|

NO. |

8002

|

Main motor |

3.0KW 2pole |

|---|---|

Oil pump motor |

3KW |

Oil pump |

VP-40 duplex pump |

| Processing length | 50mm-5950mm |

Processing diameter |

20mm-76mm |

Capacity |

4-15/min( head round trip) |

Pulling stroke |

150mm |

Applicable range of standard saw blade |

Ø315mm-Ø400mm |

Machine weight |

4.5T(reference value) |

Servo |

1KW(Mitsubishi Japan) |

PLC |

三菱 |

Touch screen |

12"Weilun |

Other electrical appliances |

Chint |

Ball screw and guide rail |

Taiwan Hiwin |

The equipment appearance, configuration and technical parameters are for reference only, the actual products shall prevail.

|

|

-

- HEADQUARTERS

- TIANJIN COORIG TECHNOLOGY CO.,LTD

- Add: Jinghai Developing Zone of Tianjin, China

- Tell: +86 022-68676316 / 68676317 / 68676318

- E-mail: forest@coorig.com

- PRODUCTION BASE

- HUBEI COORIG TECHNOLOGY CO., LTD

- Add: Fengridadao,Developing Zone of Chongyang,Hubei, China

- Tell: +86 0715-3300166 / 3300566

- E-mail: forest@coorig.com

-

- Products

- Duct Forming Production Line

- Laser Cutting Machine Series

- Metal Insulation Pipe Production Line

- Composite Plate Duct Processing Equipment

- Flange Machines Series

- Pittsburgh Lock Forming Machine Series

- Angle Iron Flange Processing Equipment

- Square Duct Forming Auxiliary Equipment

- Round Duct Processing Equipment

- Damper Processing Equipment

- Fan Coil Equipment

- Cable Tray Production Line

- Fire Hose Production Line

- Comprehensive Support and Hanger Processing Equipment

- Services

- After-Sale Service

- Service Network

- Application

- Customer Site

- Video Center

-

WeChat Official Account

-

Mobile Browsings