-

Products

-

Duct Forming Production Line

-

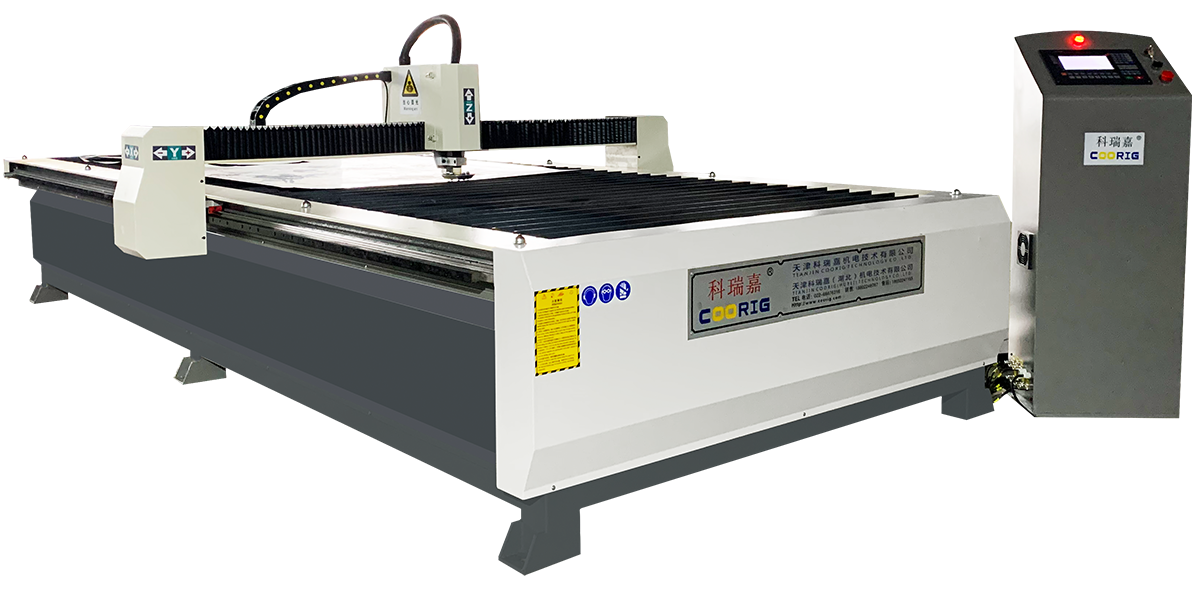

Laser Cutting Machine Series

-

Metal Insulation Pipe Production Line

-

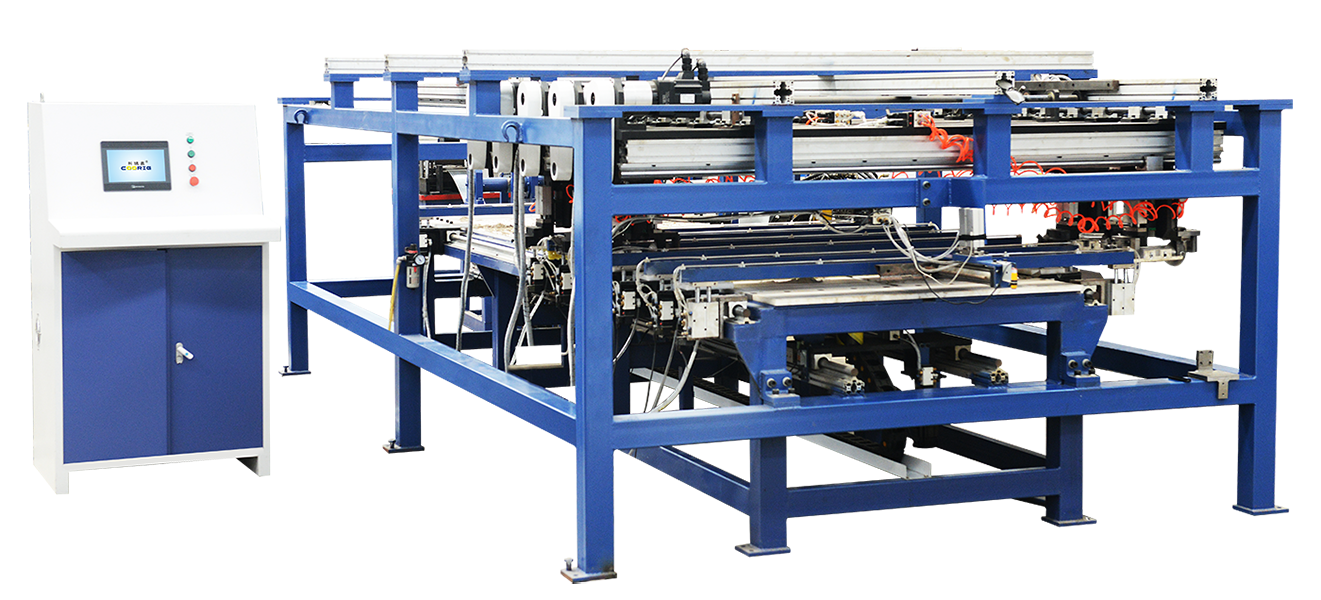

Composite Plate Duct Processing Equipment

-

Flange Machines Series

-

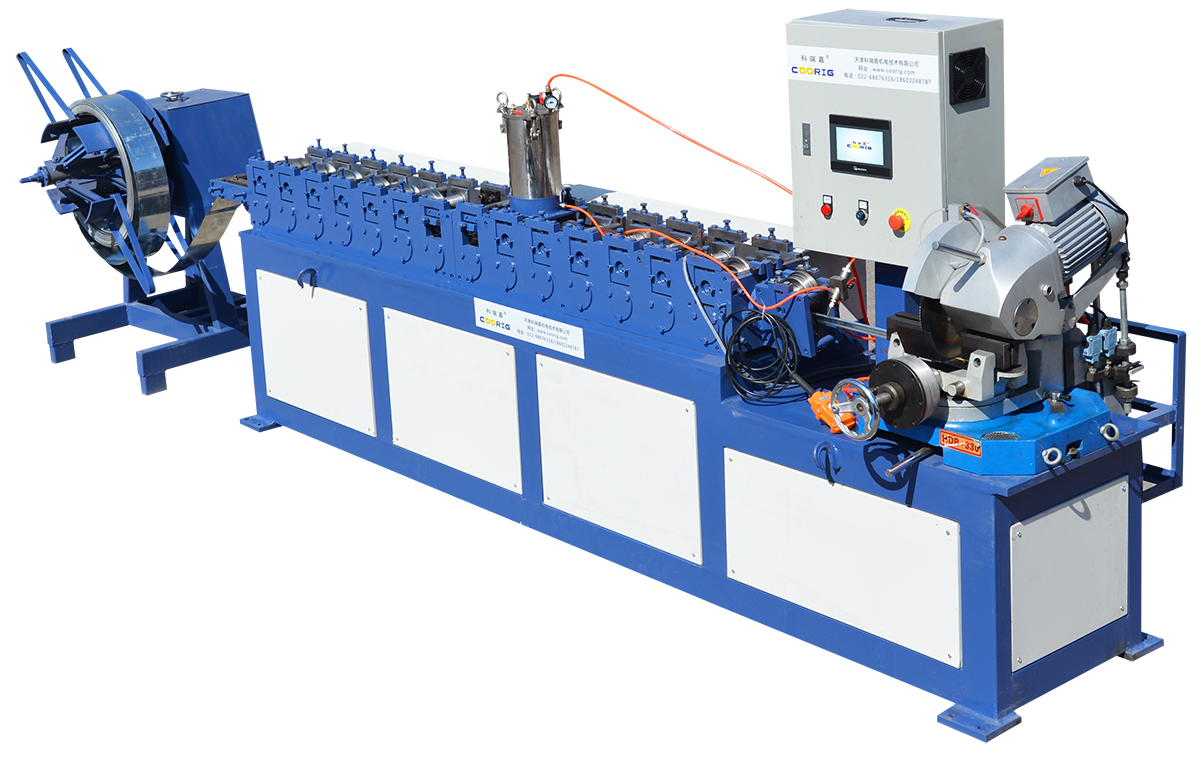

Pittsburgh Lock Forming Machine Series

-

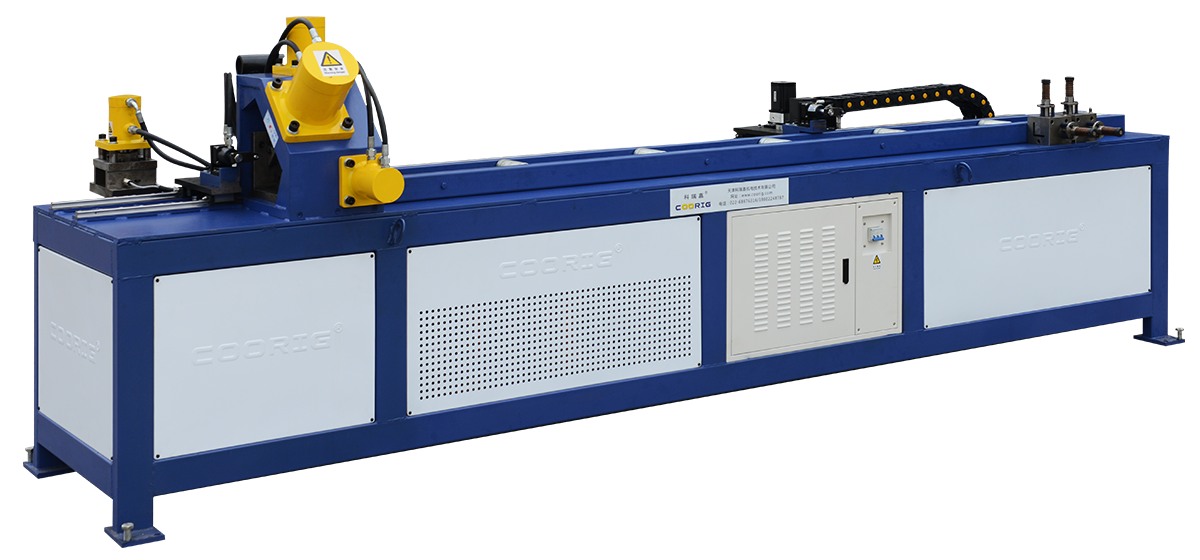

Angle Iron Flange Processing Equipment

-

Square Duct Forming Auxiliary Equipment

-

Round Duct Processing Equipment

-

Damper Processing Equipment

-

Fan Coil Equipment

-

Cable Tray Production Line

-

Fire Hose Production Line

-

Comprehensive Support and Hanger Processing Equipment

-

-

Products

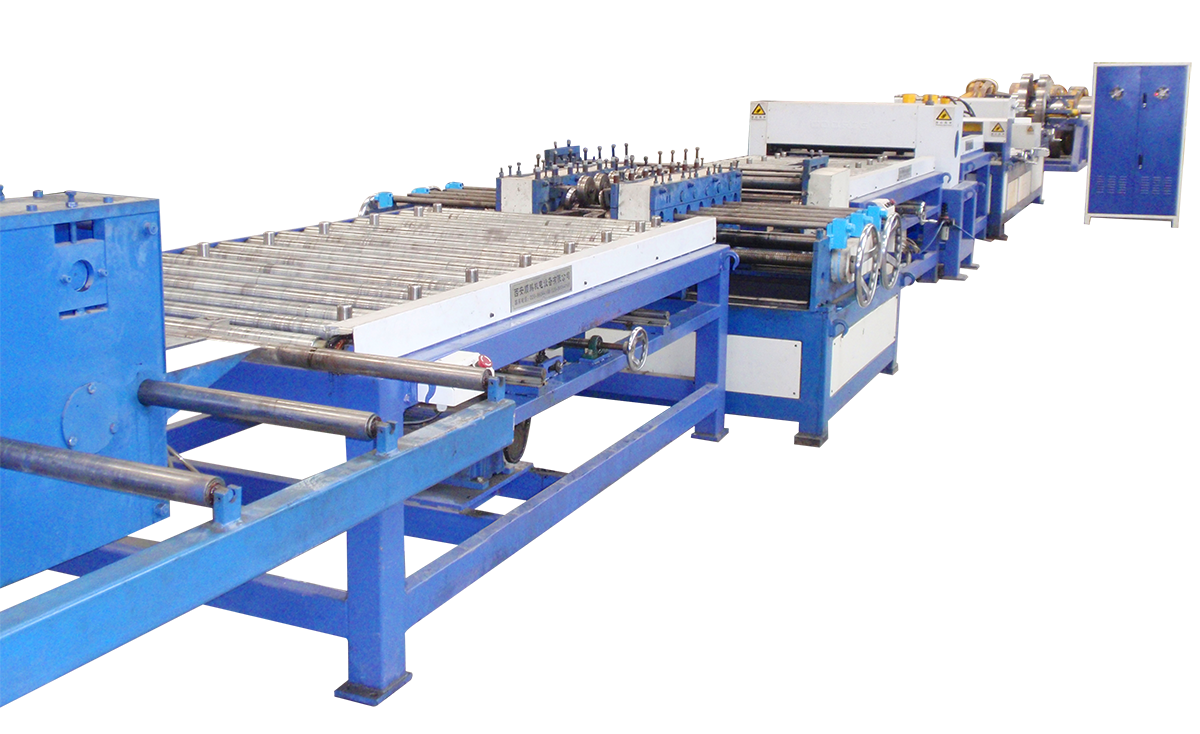

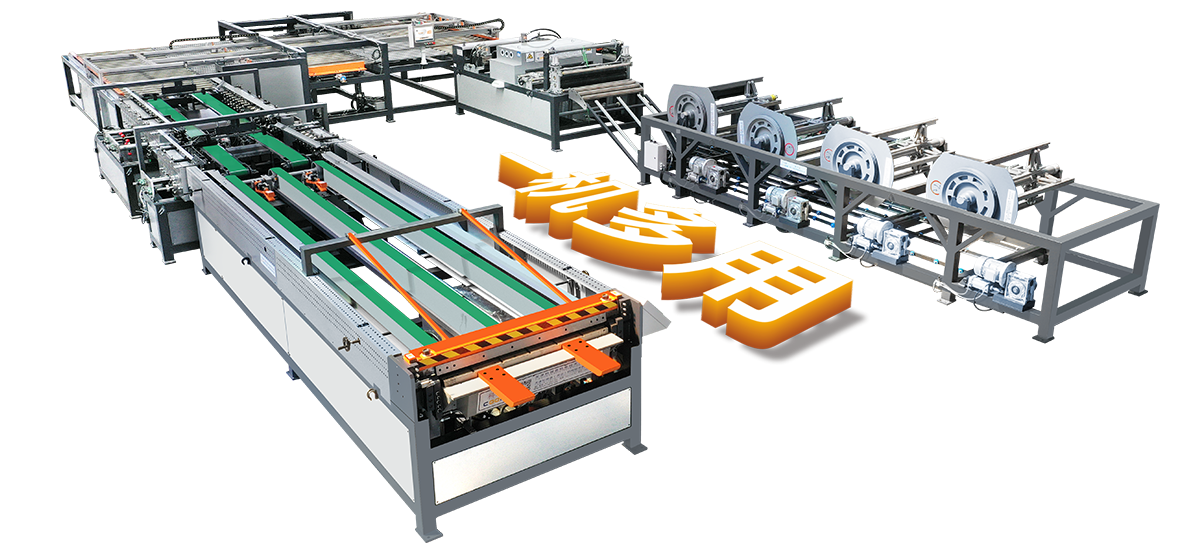

Duct Forming Production Line

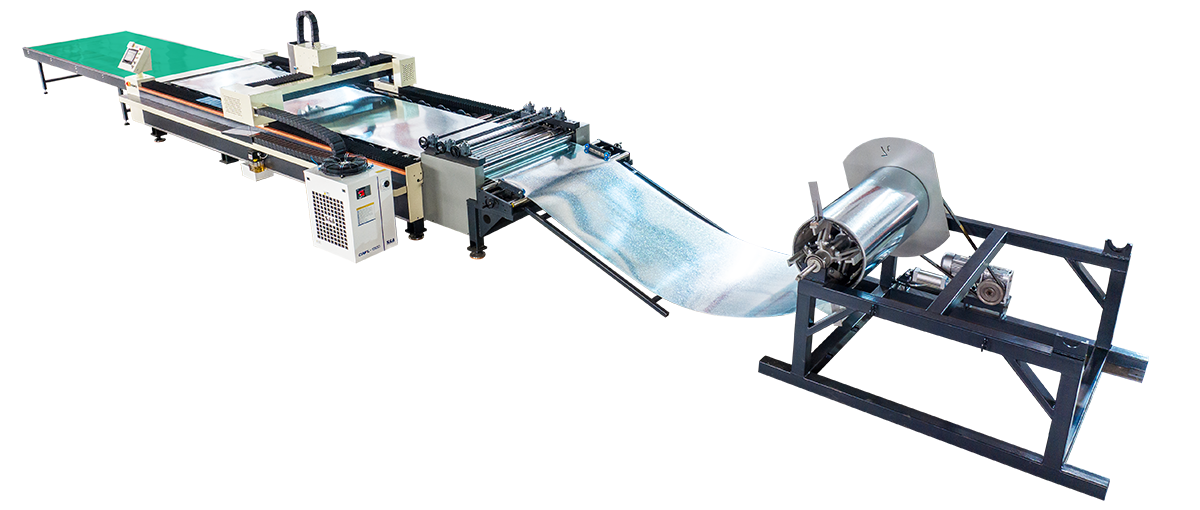

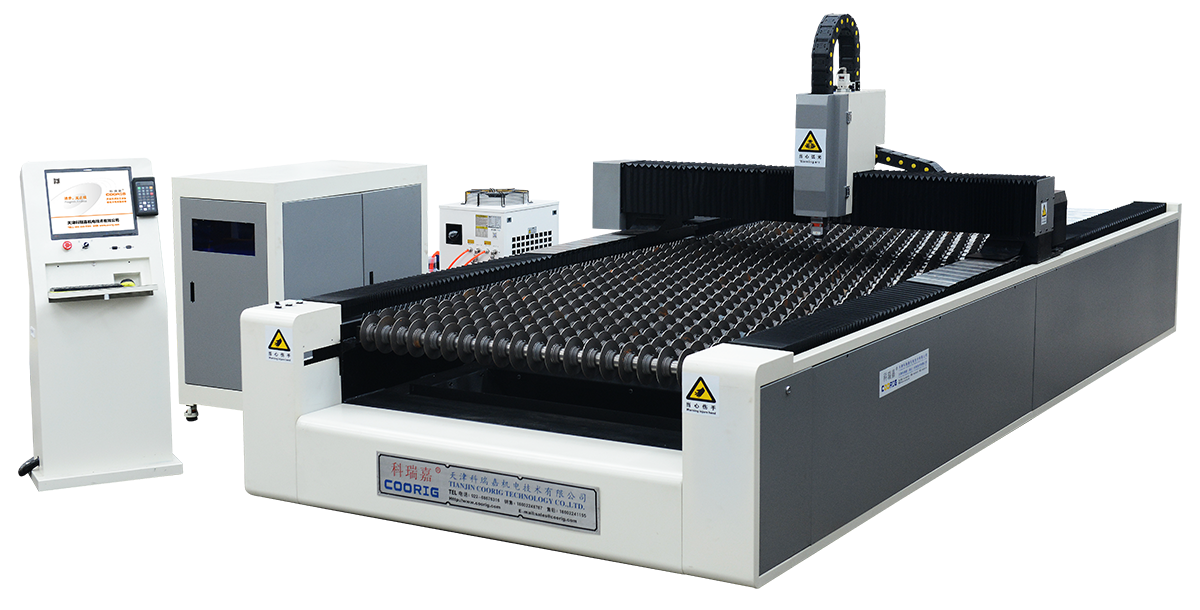

Laser Cutting Machine Series

Metal Insulation Pipe Production Line

Composite Plate Duct Processing Equipment

Flange Machines Series

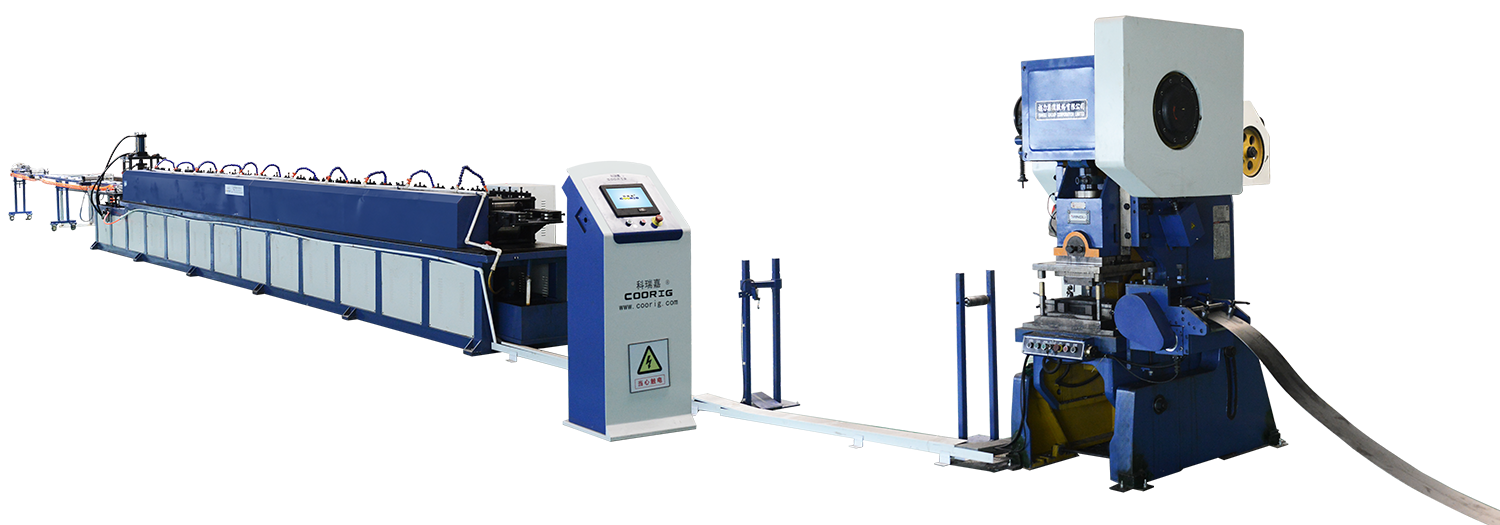

Pittsburgh Lock Forming Machine Series

Angle Iron Flange Processing Equipment

Square Duct Forming Auxiliary Equipment

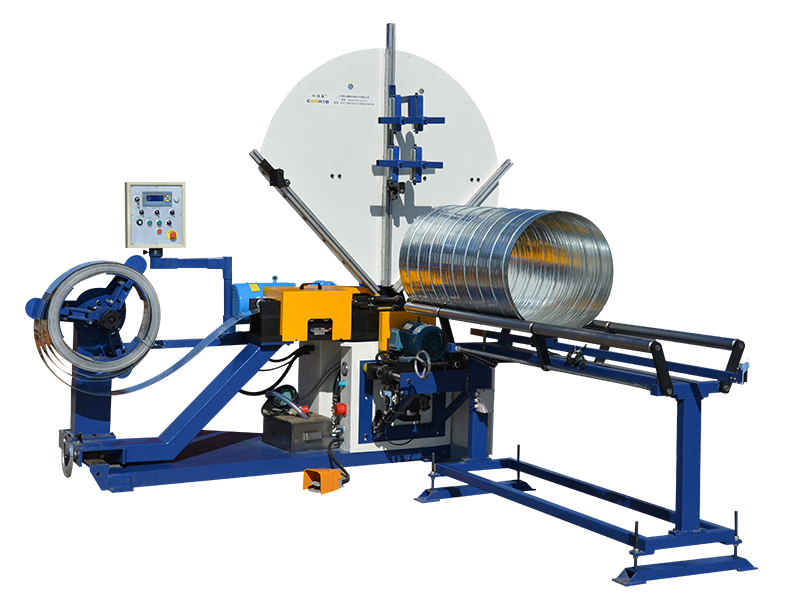

Round Duct Processing Equipment

Damper Processing Equipment

Fan Coil Equipment

Cable Tray Production Line

Fire Hose Production Line

Comprehensive Support and Hanger Processing Equipment

-

Application

-

Services

-

News

-

COORIG

-

Contact

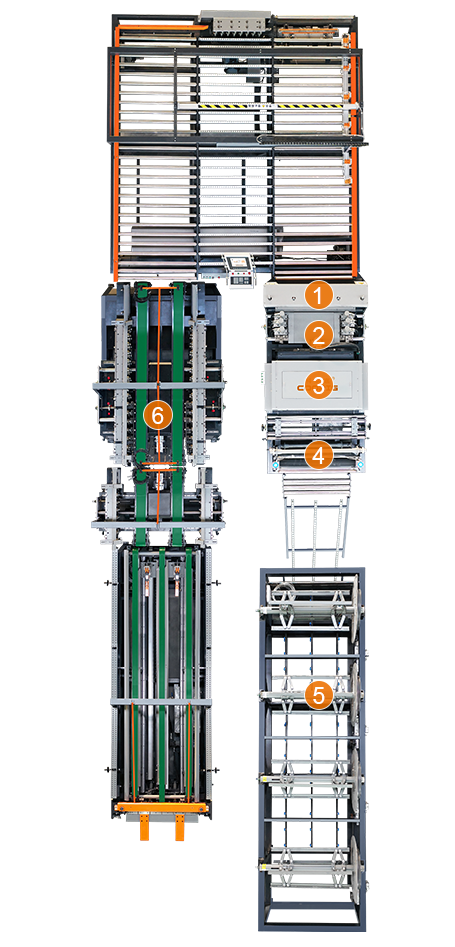

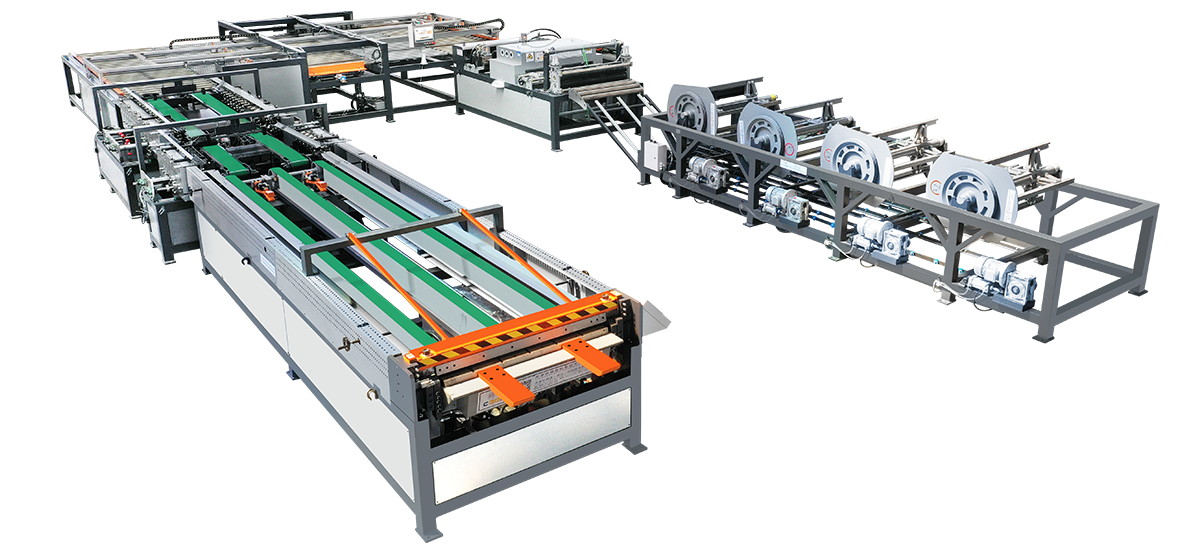

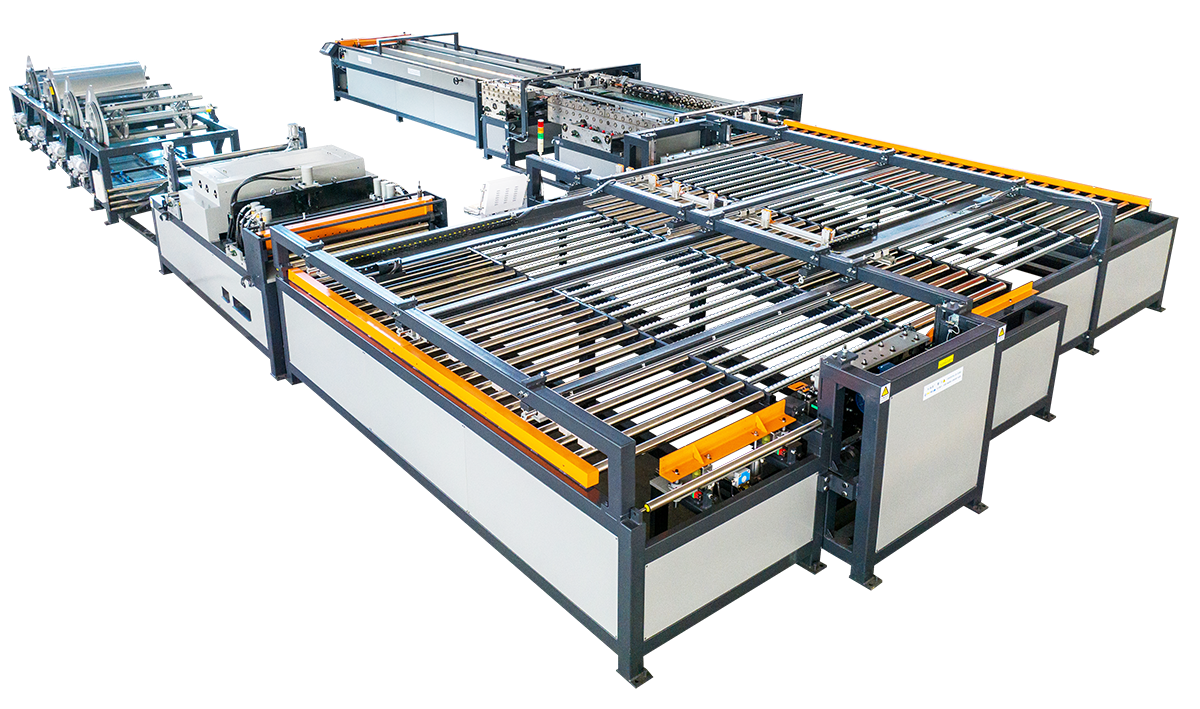

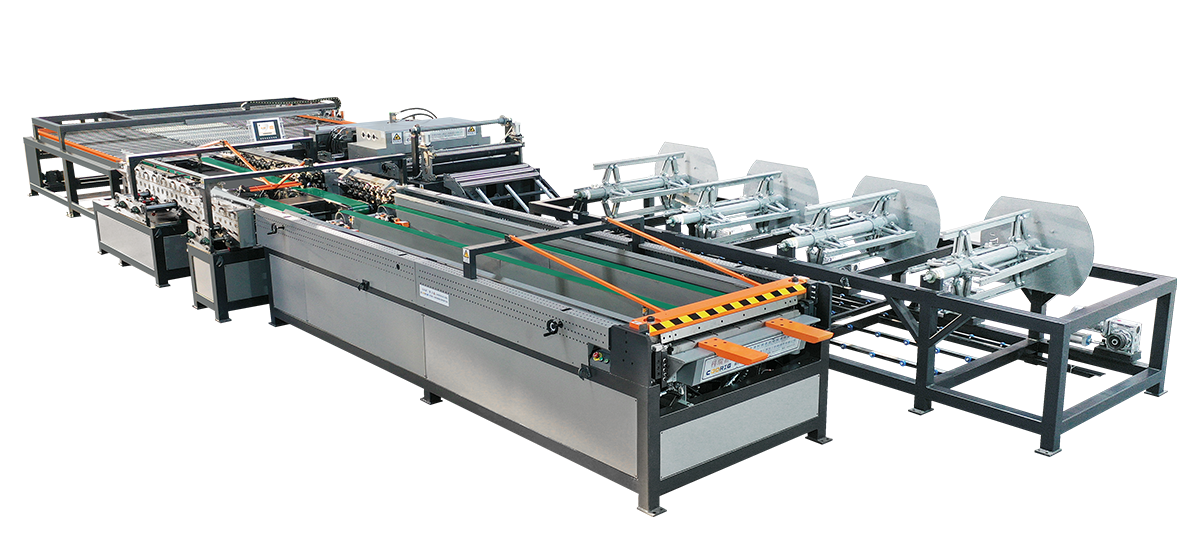

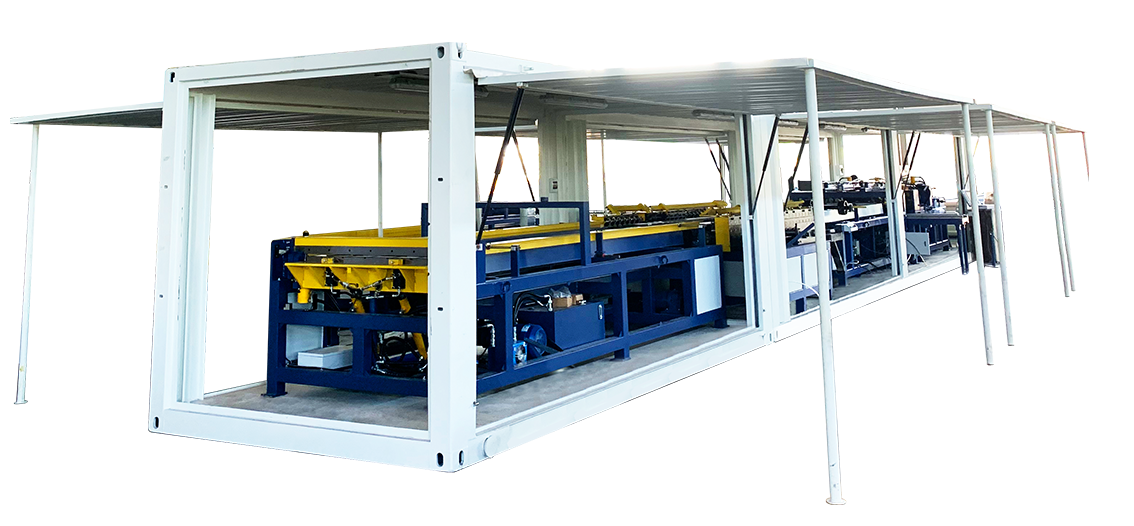

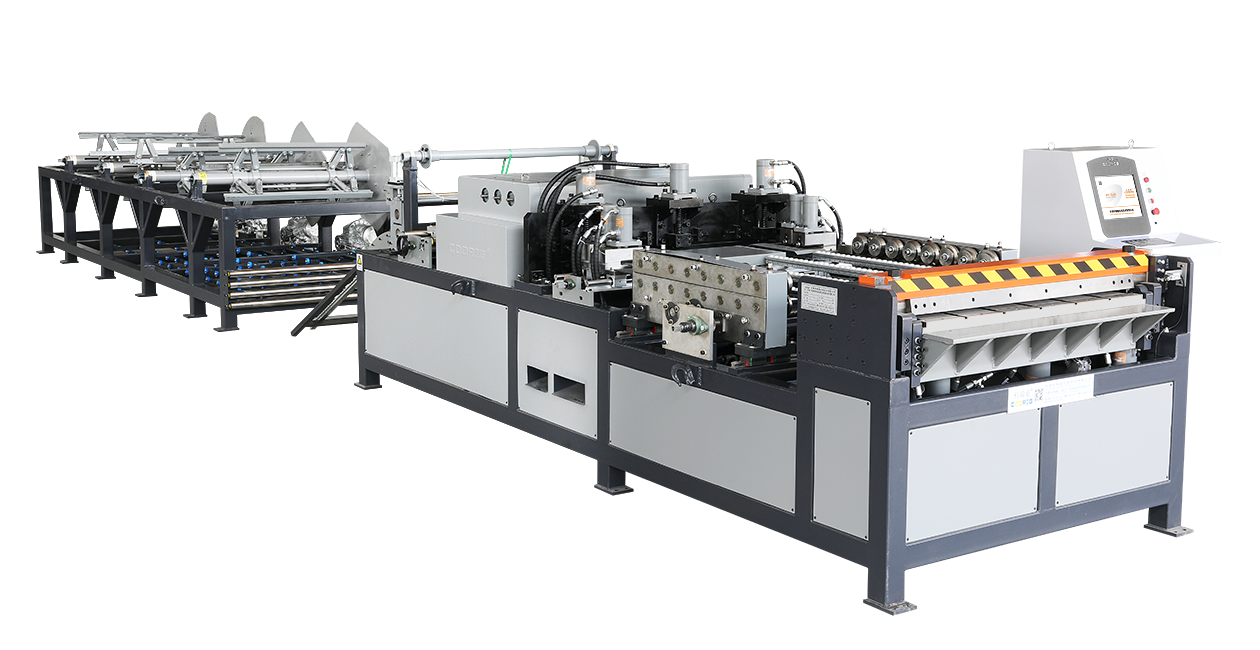

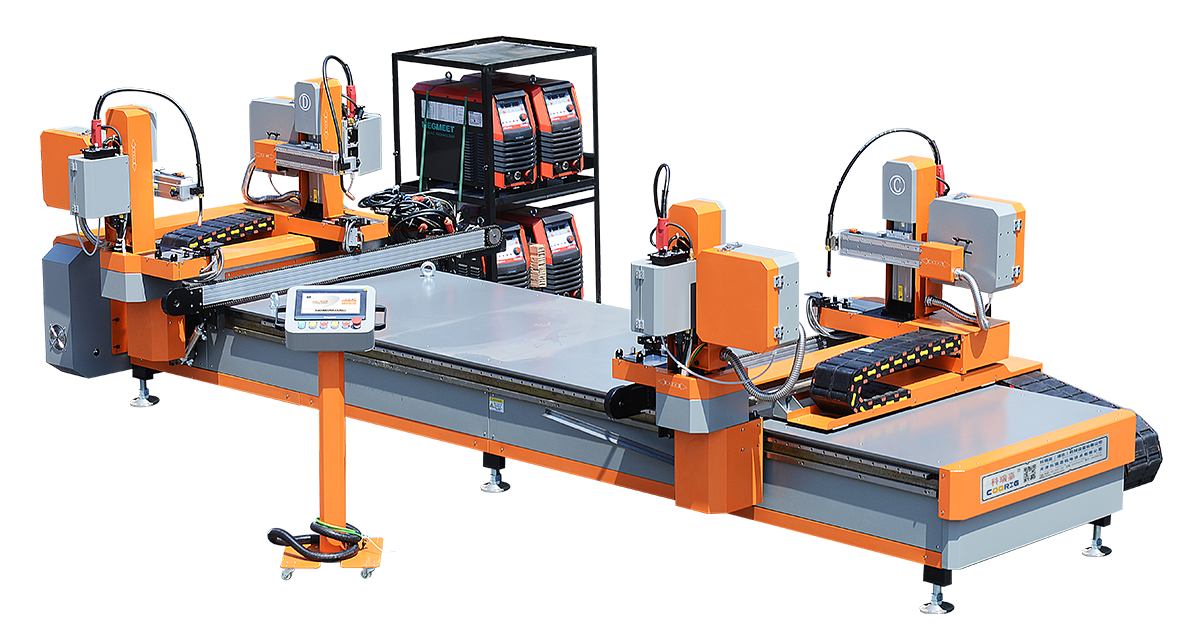

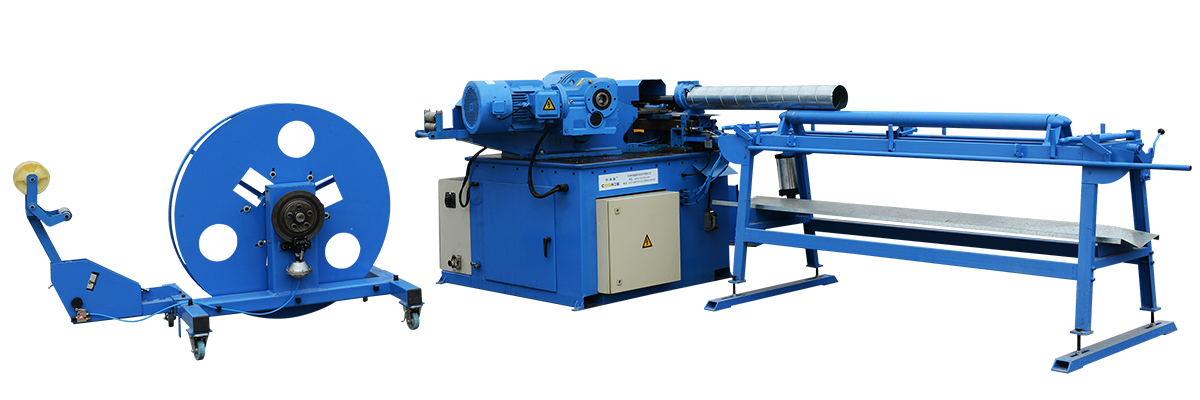

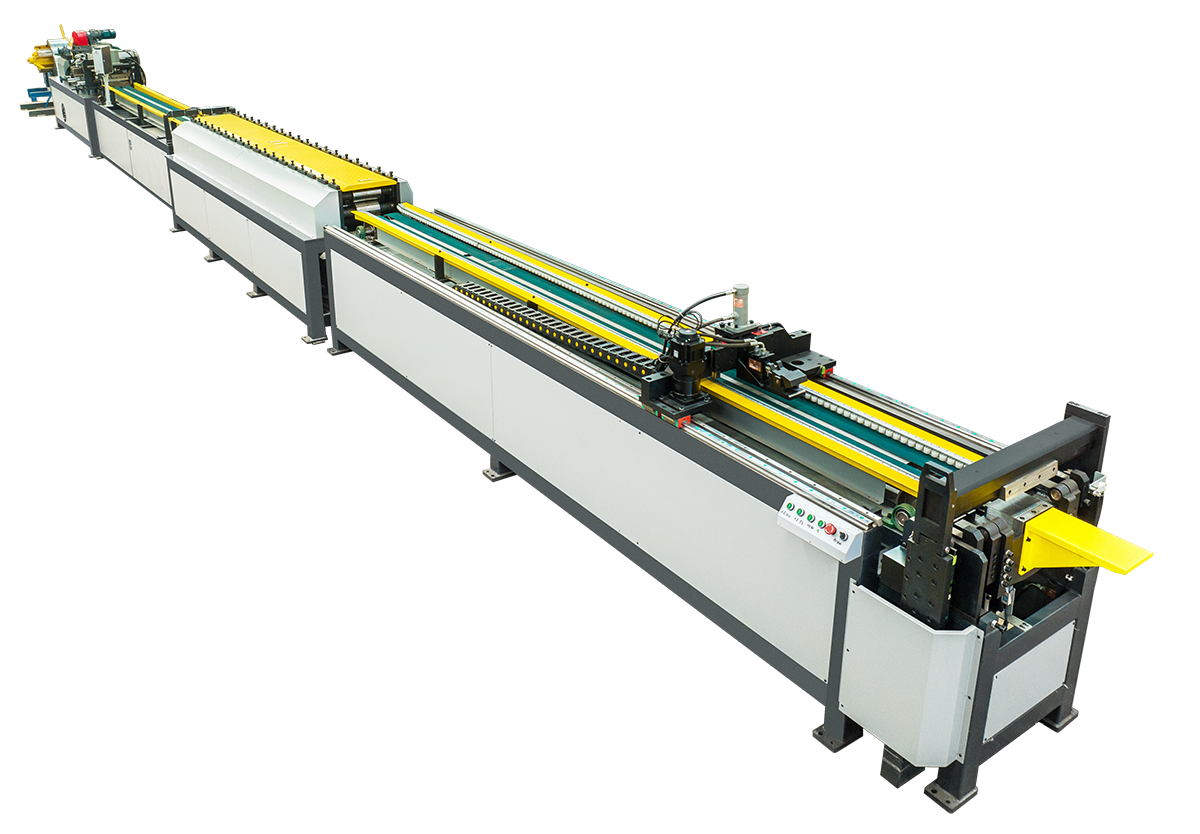

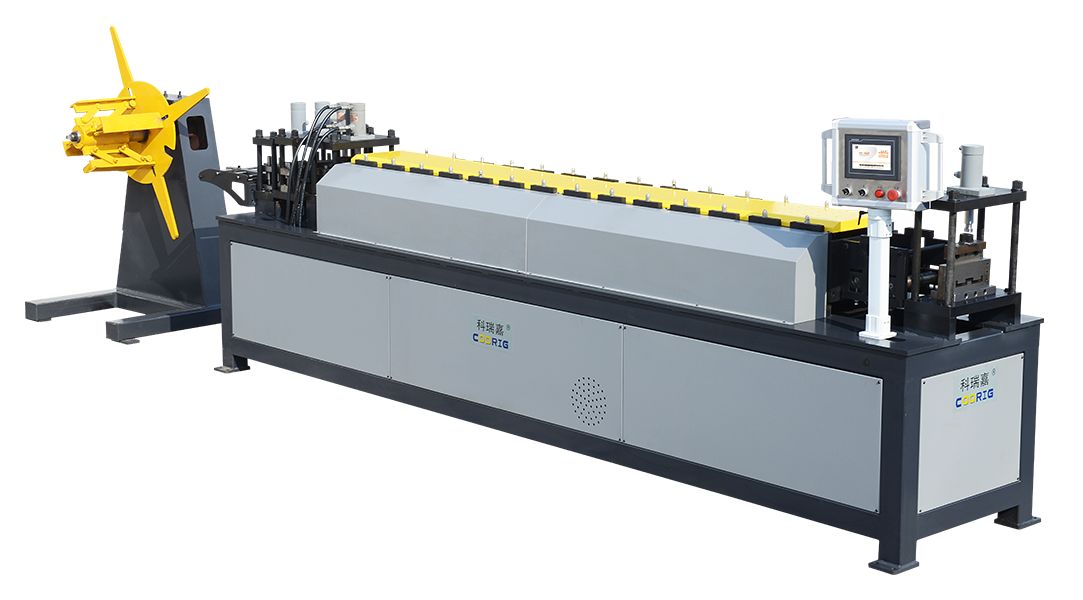

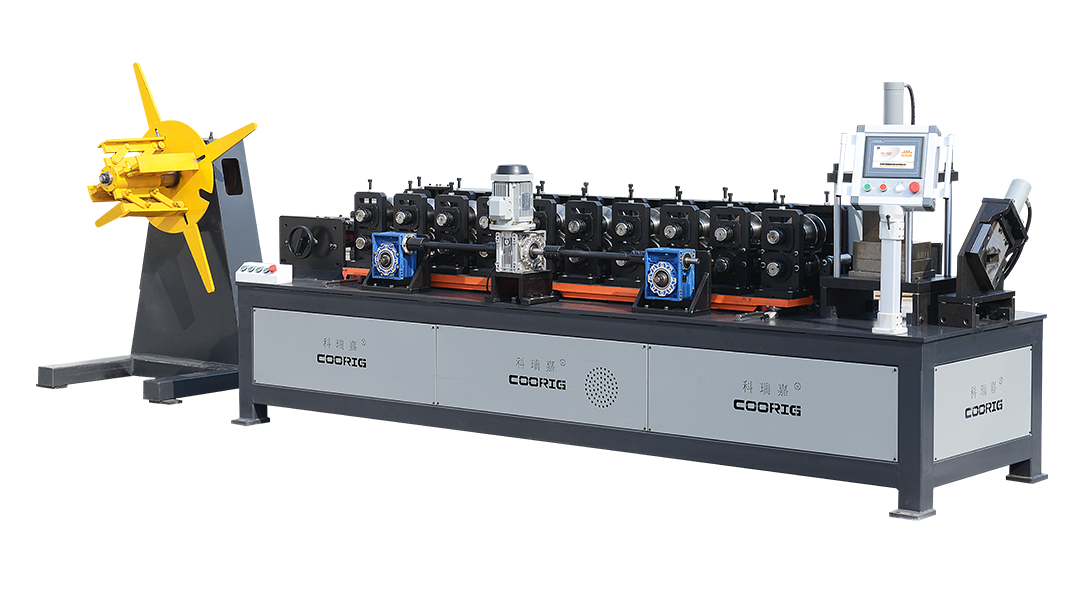

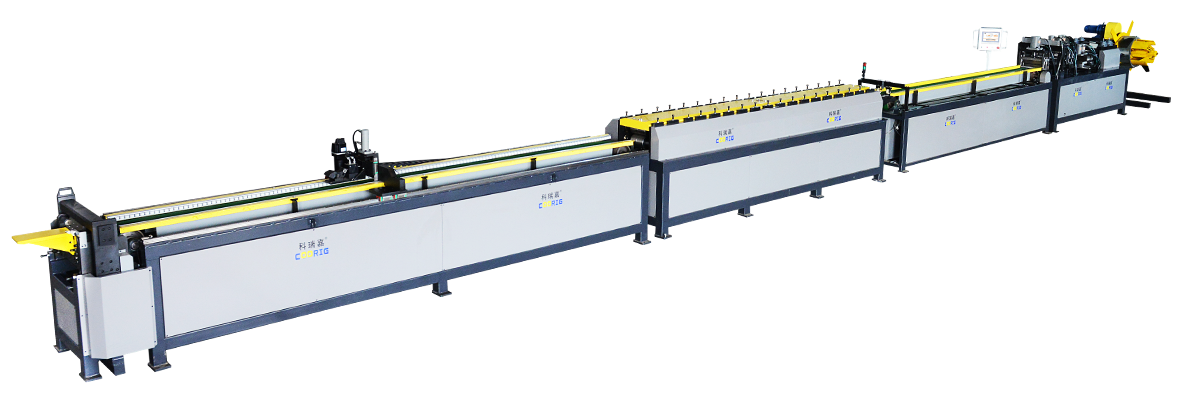

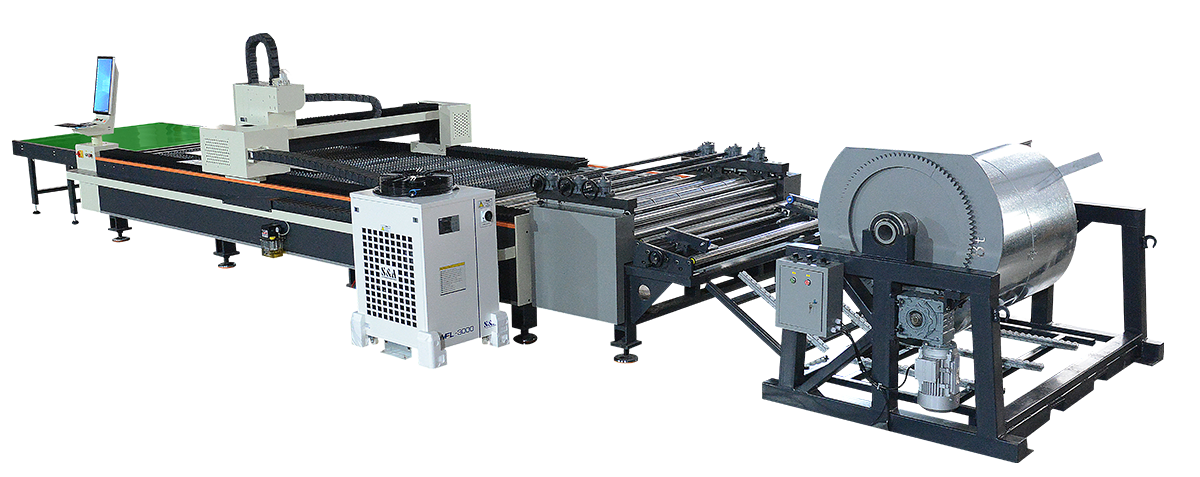

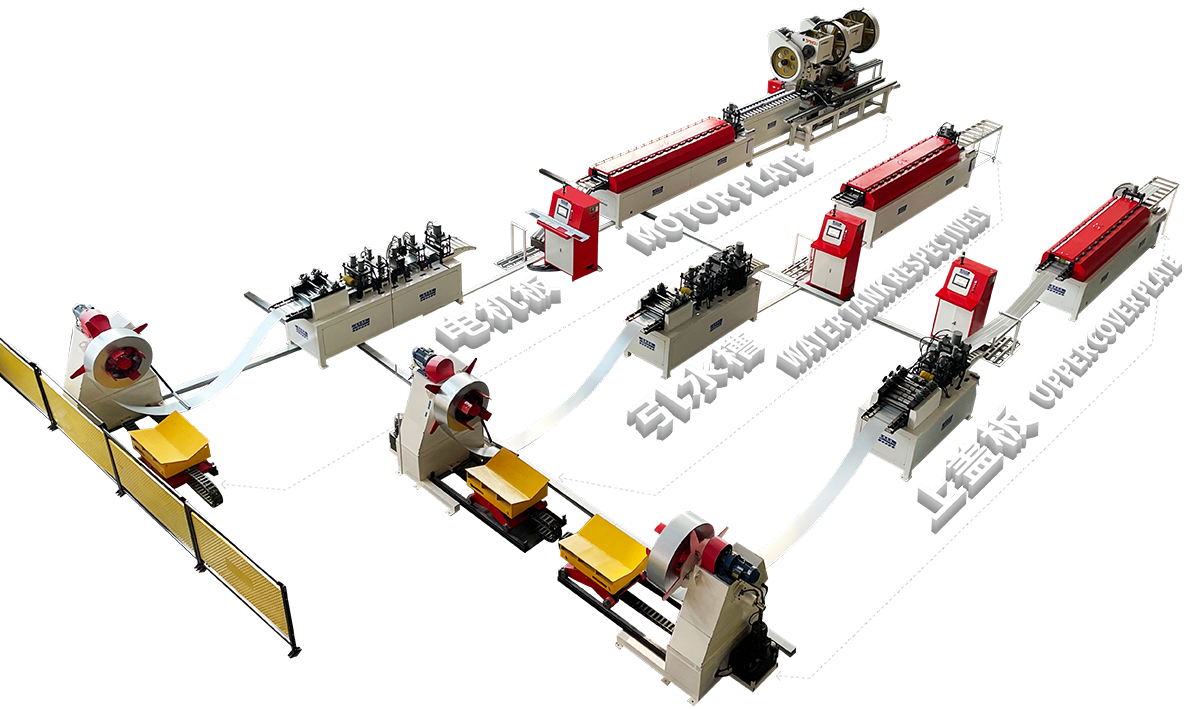

Auto Duct Line 2

It is suitable for small batch duct processing on site; Suitable for sheet blanking for cutting machine, such as Laser cutting machine.

In production, only input the size of the duct to be processed and the production line can automatically complete uncoiling, leveling, beading, notching and punching, cutting to length.

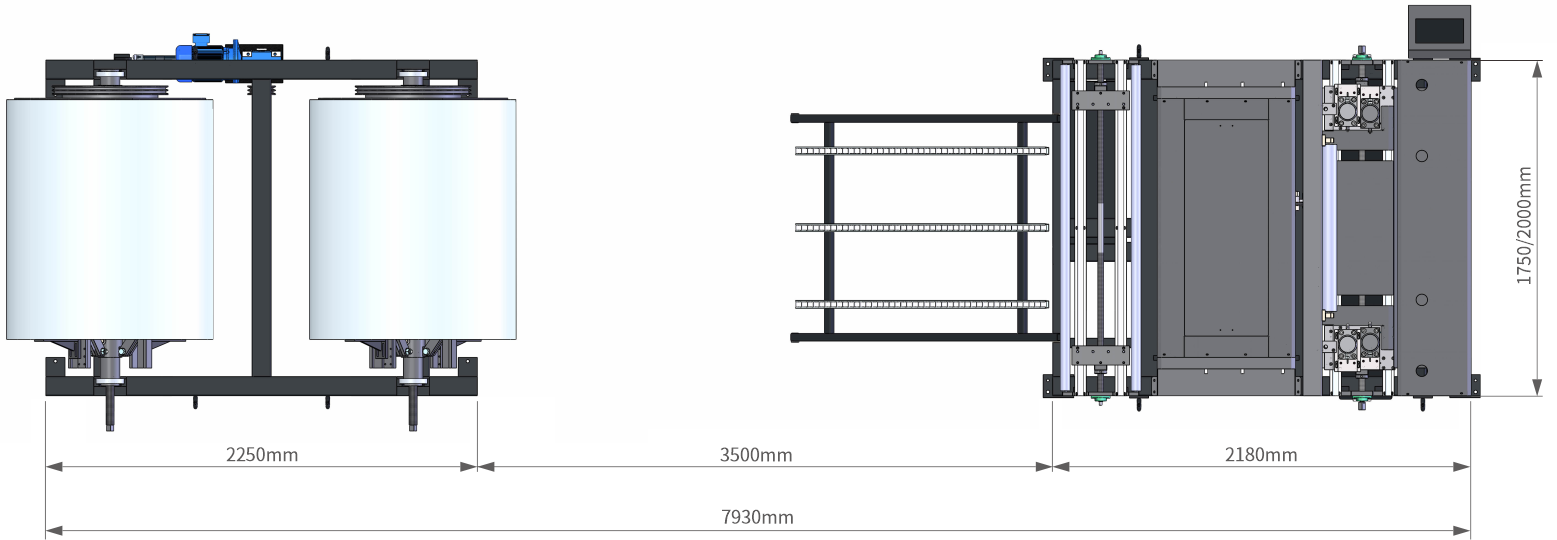

BASIC CONFIGURATION

1. One electric integral de-coiler, include 2pcs of 7tons coilers;

2. A main machine;

3. A CNC system.

WORK FLOW

MAIN TECHNICAL DATA

NO. |

Model |

Capacity in mild-steel

|

Max-width |

Max-working |

Coiler |

Dimensions |

Power |

Weight |

|

1025

|

ADL-L2C12S08-1250 | 0.5-1.2 Galvanized steel 0.5-0.8 Stainless steel |

1250 | 15 | 7000 | 7950×1750×1500 | 9 | 3000 |

|---|---|---|---|---|---|---|---|---|

| 1026 | ADL-L2C15S12-1250 |

0.5-1.5 Galvanized steel

|

1250 | 15 | 7000 | 7950×1750×1500 | 9 | 5500 |

| 1027 | ADL-L2C12S08-1500 |

0.5-1.2 Galvanized steel

|

1500 | 15 | 7000 | 7950×2000×1500 | 9 | 3500 |

|

1028

|

ADL-L2C15S12-1500 | 0.5-1.5 Galvanized steel |

1500 | 15 | 7000 | 7950×2000×1500 | 9 | 6000 |

|

The equipment appearance, configuration and technical parameters are for reference only, the actual products shall prevail.

|

||||||||

-

- HEADQUARTERS

- TIANJIN COORIG TECHNOLOGY CO.,LTD

- Add: Jinghai Developing Zone of Tianjin, China

- Tell: +86 022-68676316 / 68676317 / 68676318

- E-mail: forest@coorig.com

- PRODUCTION BASE

- HUBEI COORIG TECHNOLOGY CO., LTD

- Add: Fengridadao,Developing Zone of Chongyang,Hubei, China

- Tell: +86 0715-3300166 / 3300566

- E-mail: forest@coorig.com

-

- Products

- Duct Forming Production Line

- Laser Cutting Machine Series

- Metal Insulation Pipe Production Line

- Composite Plate Duct Processing Equipment

- Flange Machines Series

- Pittsburgh Lock Forming Machine Series

- Angle Iron Flange Processing Equipment

- Square Duct Forming Auxiliary Equipment

- Round Duct Processing Equipment

- Damper Processing Equipment

- Fan Coil Equipment

- Cable Tray Production Line

- Fire Hose Production Line

- Comprehensive Support and Hanger Processing Equipment

- Services

- After-Sale Service

- Service Network

- Application

- Customer Site

- Video Center

-

WeChat Official Account

-

Mobile Browsings